Table Of Content

Packaging is a vital part of every product. In the packaging industry, first impressions are everything. To serve this purpose, different finishing techniques can help to elevate your packaging game.

UV coating is one innovative technique that has changed the packaging industry. It is getting popular in different industries, due to its enhanced durability and sleek finish.

In this blog, we’ll discuss UV coating, how it works, and why it is essential for premium packaging. We’ll also review its applications and pros and cons. So, let’s start our journey!

What is UV Coating?

UV coating is short for ultraviolet coating. In this process, a liquid coating is applied to a surface and instantly cured with UV light. This curing method solidifies the coating and enhances the overall finish of the product, providing a professional look.

Key Features of UV Coating

Following are the key features of UV coating, let’s explore them:

- High Gloss Finish

It creates a shiny and reflective surface.

- Durability

This coating offers excellent resistance against scratches and moisture.

- Fast Application

The UV curing process is quick. As a result, it is perfect for high-volume production.

It is usually used on paper, stickers and labels to provide a luxurious look. It can also be used as spot UV. Specific areas, such as logos or text, are highlighted in it.

To fully understand this technique, let’s review different types of UV coatings.

Types of UV Coating

UV coatings have many forms. Let’s have a look at them:

1. Gloss UV Coating

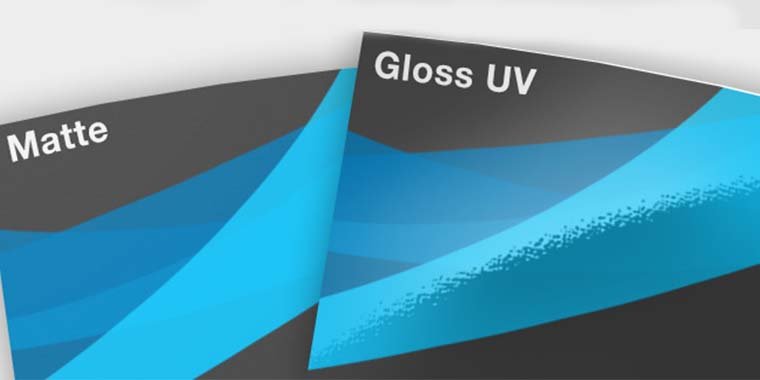

It offers a high-shine finish that provides vibrancy. It creates a reflective surface, which is ideal for luxury packaging and marketing materials.

2. Matte UV Coating

It provides a smooth, non-reflective finish that adds elegance and sophistication.

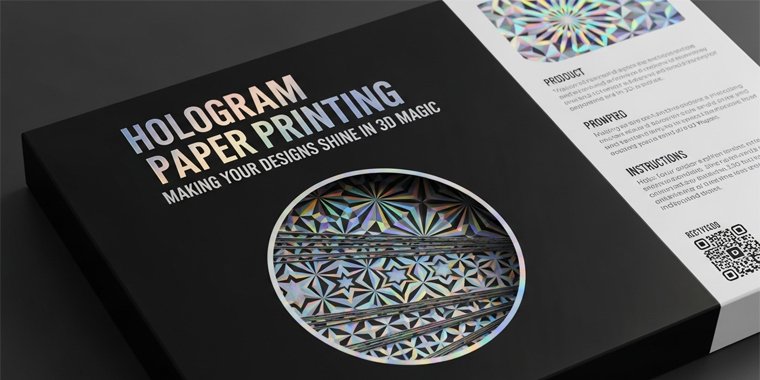

3. Spot UV Coating

It highlights specific areas of the design, such as logos or text.

4. Raised UV Coating

It adds a three-dimensional texture to selected areas. This makes the designs more engaging and interactive. This is perfect for custom bags.

Each type of UV coating serves a unique purpose. This helps businesses to align their packaging aesthetics with brand values. Moving on, let's discuss the different applications of UV coating, like what is UV coating on business cards?

Applications of UV Coating in Packaging

UV coating is a versatile solution. It enhances both aesthetics and functionality. Here are some of its popular applications:

1. Business Cards

The UV coating on custom business cards provides a professional finish that leaves a lasting impression.

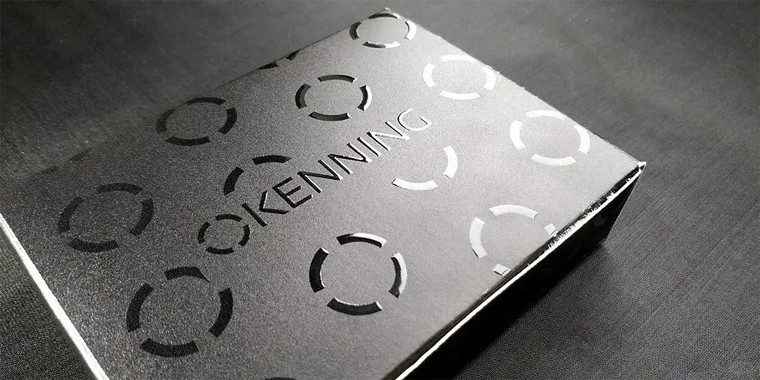

2. Luxury Packaging

High-end products often use spot UV coating to create a premium feel.

3. Promotional Materials

UV-coated promotional materials are durable and visually appealing, such as brochures and flyers.

4. Food Packaging

UV coating offers great protection, but a specific formulation is required for its direct contact with food.

After discussing the applications of this technique, let’s explore its pros and cons for a thorough understanding.

What are the Advantages and Disadvantages of UV Printing?

UV coating has different strengths and limitations, which can influence its suitability for your packaging needs. Here’s a detailed look:

Advantages

- Provides a high gloss or matte finish for a premium look.

- Protects against scratches, moisture, and fading.

- Fast curing process ensures quicker production.

- Modern UV coatings are environmentally friendly.

- Ideal for large-scale production due to quick processing.

Disadvantages

- Not suitable for a natural design or finish.

- Can crack or peel under extreme conditions.

- Requires specialized equipment.

- Non-recyclable in some cases, depending on the base material.

- Higher upfront costs compared to traditional finishes.

By understanding the strengths and weaknesses of UV coating, businesses can make wise decisions to use this method in their packaging. Want to target a wider audience, including eco-conscious customers? Are you thinking of going for UV coating? Let’s see if it is eco-friendly or not!

Coating Environmentally Friendly?

Yes! It can be environmentally friendly, but it depends on the material used and how those are applied. The use of greener alternatives has become a focus point in packaging.

Water-based UV coatings and UV light curing technologies consume less energy. This helps to reduce the environmental impact.

Following the growing trend of UV coating in the market, it is perfect for eco-conscious brands when used with white cardboard boxes.

Wondering, “Do you need UV coating for your packaging?” Let’s find out.

Does Your Packaging Really Need UV Coating?

Deciding to use UV coating depends on your packaging goals, budget, and product type. Here are some key factors to consider:

Brand Positioning

If you’re aiming for a premium look, UV coating can enhance the perceived value and visual appeal of your packaging, like for luxury jewelry boxes.

Product Protection

If your packaging requires resistance against scratches or fading, UV coating provides a durable layer of protection.

Target Audience

For industries like cosmetics, luxury goods, or food, a sleek and glossy finish can create a lasting impression.

Budget Considerations

While UV coating adds an elegant touch, it comes with additional costs. Make sure it is within your budget and packaging requirements.

If your goal is to outshine your competitors and protect your products, then UV coating is a good investment.

Also read: How Spot UV A Prominent Coating Makes The Packaging Eye-Catching?

Wrapping Up: Choose Us to Uplift Your Packaging with UV Coating

As we’ve discussed, UV coating enhances durability and your brand’s appeal. So, if you need a high-gloss shine, a matte finish, or spot UV highlights that are game-changers in premium packaging, choose us because we offer:

- Different UV Coatings

- High-Quality Materials

- Eco-Friendly Choices

- Expert Craftsmanship

- Affordable Pricing

Upgrade your packaging with our Custom Designs Boxes. Contact us today via email at sales@customdesignsboxes.com to get started.