Table Of Content

Foil stamping is a printing technique that provides grace to packaging. A layer of foil is applied to a surface with heat and pressure in this method.

This enhances branding in the packaging industry. It also uplifts the perceived value of the products. That’s why knowing about this method is beneficial for you if you are a business owner or want to start one.

In this blog post, we’ll analyse foil stamping printing in-depth. We’ll explore how foil stamping works, its benefits, and its applications. So, why wait any longer? Let’s get started!

What is Foil Stamping?

It is also known as hot foil stamping. It is a printing process that uses heat and pressure to create a shiny design. It does not use liquid ink instead, it uses foil.

The foil is pressed with a heated die on a surface. This transfers the design onto different materials, such as paper, cardboard, or leather.

It offers numerous finishes and textures. It is a popular choice for custom bookmarks and many other items.

How Does Hot Foil Stamping Work? 5 Quick Steps

You might think, “what is the process of hot foil stamping?” It involves five steps. Let’s review them:

Step 1. Design Preparation

A metal die with the design is created. This die will be heated and used to apply pressure to the foil.

Step 2. Foil Selection

The right type of foil is selected like gold foil stamping, silver foil stamping, or white foil stamping.

Step 3. Heating the Die

The die is heated to the appropriate temperature to activate the adhesive layer on the foil.

Step No 4. Applying Pressure

The heated die is pressed onto the foil, which is placed over the packaging material. The heat and pressure transfer the foil design onto the surface.

Step No 5. Final Touches

Excess foil is removed. It leaves a clean and polished finish.

Foil stamping adds exclusivity to products. This makes them more appealing to consumers—for example, luxury chocolate boxes and apparel boxes.

Types of Foils

Foil stamping offers numerous foils for different packaging needs. These are:

- Metallic foil: provides a reflective surface to metallic labels and other materials.

- Pigmented foil: offers solid colors with a matte or glossy finish.

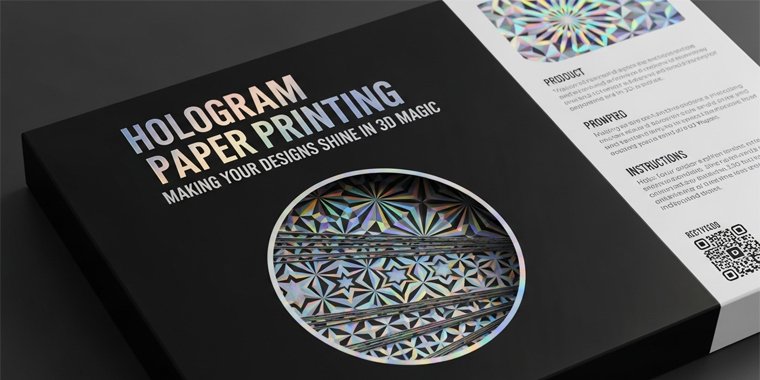

- Holographic foil: produces a rainbow effect that changes with light. It is mostly used for collectable items.

- Pearl foil: offers an iridescent sheen that subtly enhances packaging.

- Clear Foil: adds a glossy or matte finish without any color. It provides minimal packaging designs.

Common Foil Stamping Machines

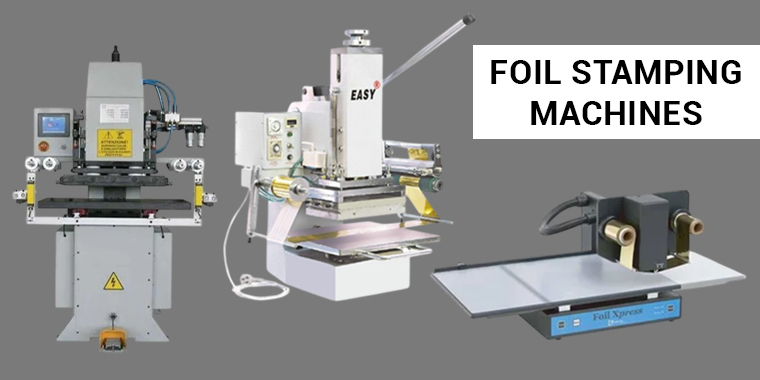

The results of foil stamping depend on the type of machine. Some of the most common foil stamping machines include:

Hot foil stamping machine: It uses heat and pressure to transfer the foil. These are suitable for different materials.

Automatic hot foil stamping machines: They automate the process and ensure consistency in mass production.

Hot foil stamping machine for paper: It is used for products like custom business cards and book covers.

Digital foil stamping machine: It uses digital printing technology and doesn't need metal dies. This reduces the setup time.

Foil stamping printer: It is a compact machine for small-scale foil stamping projects. It is used for personalized packaging.

Leather foil stamping machine: It’s designed for stamping on leather products, such as book covers and accessories.

Applications of Foil Stamping in Packaging Printing

Foil stamping is extensively used in the packaging industry to enhance product presentation. Some common applications include:

Luxury Product Packaging

Premium brands use gold foil printing and silver foil stamping on boxes and labels to create a high-end look. The shine and reflective properties grab attention instantly.

Business Cards and Marketing Materials

Foil stamping business cards and other materials add elegance. This helps brands leave a lasting impression by showing professionalism.

Book Covers and Stationery

Many publishers use foil stamping for book covers to create visually stunning designs. DIY enthusiasts also use foil-stamping book covers for personalization.

Hang tags

Foil stamping helps to make your promotional materials more attractive to customers.

Benefits of Foil Stamping

Foil stamping offers several advantages for businesses. These are as follows:

- Its shiny effect attracts customers and enhances brand perception.

- The stamped foil does not fade or smudge like ink-based printing. This ensures a visual impact that lasts longer.

- Various colors and finishes are available allowing companies to customize packaging according to their packaging needs.

- Many foils are recyclable. This makes them a greener alternative when used with environmentally friendly materials.

- They enhance product visibility and reinforce brand identity. Due to this, items become more appealing for the customers.

Also Read: A Depth Overview Of Hot Foil Stamping: 101 Course

Summing Up:

Foil stamping is an amazing technique that enhances the look of packaging. It offers different colors and adds a premium touch to your products.

It is a durable branding solution. As businesses continue to look for ways to stand out, foil stamping remains a popular choice for eye-catching packaging design.

If you want excellent results from foil stamping, we at Custom Designs Boxes can assist you. Contact us via email today at sales@customdesignsboxes.com to learn more!