Table Of Content

Die cutting is one of those finishing techniques often used alongside printing, and many of us have most likely encountered it without knowing the name of the process. Have you ever received a business card with rounded corners? Or purchased a sticker that is cut in the specific shape of the logo? That is exactly die cutting.

Alongside die cutting in printing, this process allows you to cut different types of materials into custom shapes using various techniques and methods. Die cutting machines are used for packaging, marketing, and labeling.

The article explains how die cutting works, describes various types of die cutting machines, and highlights popular applications of die cutting. If you are simply interested or considering applying die cutting to your own brand, you will get all the necessary information here. Keep reading!

What is a Die?

A die is a specialized tool with a customized shape, designed according to your specifications, and it is used to cut or shape materials such as metal or plastic. A Die has sharp edges that cut various kinds of materials, giving the object an accurate or attractive look.

What is Die Cutting in Printing?

The purpose of die cutting in printing is to add compelling designs to labels, papers, cardstocks, and more. The die will cut the printed part on the surface of cardboard gift boxes or paper, which shows the impressive die-cut designs on its surface. The technique will enhance the visibility of printed and graphics imagery on your packaging, stickers, and labels.

In addition, you can use die cutting to cut the surface of the material based on the shape of the brand logo to get more deals and enhance brand visibility.

What is the Importance of Die Cutting in Printing?

Die cutting has significant importance in the printing industry. It changes the creation of custom shapes and designs that cannot be done by using traditional methods. The customization will make the printing pieces more appealing and compelling, which is helpful for marketing materials and leaves a lasting impression.

Moreover, die cut is also used to make custom index tabs, cut holes or hooks for custom door hangers and tags, add business card slits in brochures or folders, create fold-out sections, rounded corners, and other noticeable features that increases the functionality of the printed products.

Types of Die Cut Techniques

Various types of die-cut techniques are used to shape objects based on your needs and preferences. Let’s explore the three popular and common die-cut techniques that are used to cut and shape manufacturing and other items.

1. Rotary Die Cutting

Rotary die cutting is one of the most useful methods that helps users to cut several regular shapes quickly. A revolving metal die plays an important role in this method by rotating, and a cardstock, flex, or other types of objects pass under it.

The die that comes in the form of a cylinder and features sharp blades. The speed of the rotating die determines the lengths of the shapes, making it particularly helpful for high-volume cutting.

2. Laser Die Cutting

Laser die cutting is the first choice for users when they are cutting flexible items like foams and rubbers. The best part about this method is that it can also be used to cut small holes and fenestrations.

In the market, many types of laser cutting machines are available, but two of the most popular ones are sheet-fed gantry lasers, that is more suitable for small-scale cutting. The other one is a web-fed-in-line laser cutting machine, which is perfect for large-scale cutting.

3. Flatbed Die Cutting

The third type of die-cutting technique is flatbed die-cutting, which is also an exceptional method for cutting various shapes in low-volume projects. You can use this method to cut thicker sheets in less time. The process of cutting shapes by using Flatbed dies includes:

- Place the sheets under the dies that you are cutting

- The dies will be placed under the presses, and it will be primarily mechanical or hydraulic

- Once the cutting process is completed, the press and dies are removed, and the shapes can be drawn easily.

Types of Die Cutting Machines

Die cutting machines include two types, and each type is best for its specific applications and features. But, two of the best Die Cutting machines are:

- Manual Die Cutting Machine: This machine has steel-cutting dies that need to be activated manually thorugh a lever, and it is perfect for use in homes.

- Digital Machine: When using a digital machine, it is necessary to have a computer cartridge that contains an image, and it uses a sharp blade to cut materials accurately.

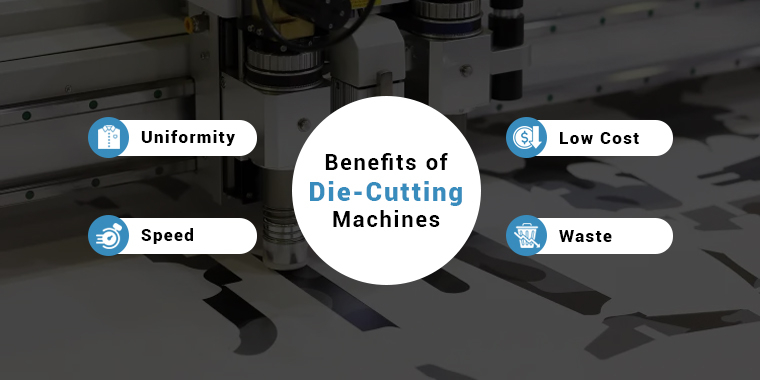

Outstanding Benefits of Die-Cutting Machines

Die cutting in printing offers numerous benefits. Some of them are as follows:

1. Uniformity

The die cut produces several identical forms that are completely based on the type of die used. Uniform shapes like cutting and box templates, making vinyl letters, or plastic parts for electronics and toys are essential in mass production. They also help you to minimize material waste and work perfectly with embossing folders.

2. Low Cost

Other cutting methods need several tools or pieces of equipment. However, die cutting only needs one computer-aided design and machine to produce the shapes. The process is more efficient with advanced die-cutting machines, and it will save several hours that are spent on manual labor.

3. Speed

One of the impressive benefits of die cutting machines is that they can create a shape with a single punch from the cutting plates and identical forms quickly. A manual die cutter also generates various shapes quickly than you can cut those designs manually. It takes a lot of time to generate complex shapes by hand

Die cutting machines can lower the loads of identical forms, and metal sheets or plastic can easily be processed through the machine. This can ultimately boost the workflow of output.

4. Reduced Waste

Dies can be lined up very accurately with the cutting plates, which allows die cutting machines to create less extra material around the shape as compared to other traditional methods. It decreases waste, saves money, and is better for the environment.

Applications of Die Cutting

Based on the above discussion, the demand for die cutting machines in the market is significantly high. That’s why they have various applications in several industries. Let’s explore some of the unique applications that you must know:

Custom Packaging Boxes:

The die cutting invention transforms the packaging industry, and it is used to shape custom bags, foldable boxes, and other types of packaging. Economically, the manufacturers in the packaging industry use this cutting method widely to make appealing custom packaging solutions for product-selling businesses.

Foam, Rubber, and Plastic:

In the Automotive industry, many types of rubber parts are properly shaped by using a die-cutting machine. Two of the most common designs of die cutting techniques are engine seals and rubber gaskets.

Various types of die-cutters can significantly cut thin sheets of plastic and make various types of products. Moreover, you can use these cutters to cut several types of foam, and they help you to make insulation, gaskets, and more.

Stickers, Cards & Labels:

One of the most common applications of die cutting is in marketing agencies, where they use it to make stickers, cards, and labels efficiently. All of these are made in a unique shape, and die cut stickers or cards are available in a small size and made of thin cardstock and paper stock.

On the other hand, business, birthday, and other cards require efficient customizations, and manufacturers use flatbed dies to shape these cards.

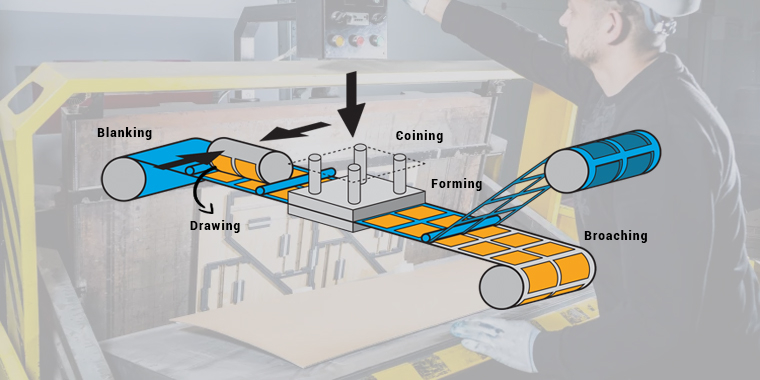

5 Useful Methods of the Die Cutting Process

When discussing die cutting methods, we encounter several essential and commonly used techniques in this process. These techniques create a possibility of new structural design and provide you with a personalized and genuine packaging experience. Here are the die cutting methods:

- Blanking: A blanking method is used to cut a flat sheet of material from its outer edge to create a certain shape. This method ensures that the material will stay flat and even.

- Drawing: It means you are stretching a material to make it thinner and longer, and it is used to shape tall and slim packaging.

- Forming: The act of shaping raw materials over a curved surface is known as forming. It is used with a design sketch to create round objects.

- Coining: Coining uses a hydraulic press to create small and detailed shapes and precise design patterns.

- Broaching: It uses large rows of cutting teeth to cut through extremely thick and dense materials.

Expert Tips for a Perfect Die Cut

It is important for packaging manufacturers to get perfect output from the die cutting process. implementing a specific cutting method and getting sharp edges and ideal shapes can be challenging when the results are not according to your preferences. Here are some of the tips that you must consider to get quality die cutting for your labels, business stickers, and packaging.

- Place the objects on the plates together so they can stick, to eliminate errors because of the displacement of objects.

- If you want to add holes, then leave a specific distance between edges and holes of the material to avoid the stock from tearing away.

- We recommend extending the artwork or color pattern printing in terms of avoiding the white spaces after cutting is done.

- Lastly, don’t forget to add dielines to the stock because they will guide you through the overall process of cutting seamlessly.

Also Read: Guide to Different Types and Advantages of Die-Cut Boxes

Conclusion

Die cutting in printing is a perfect way to give a professional look to your packaging, stickers, and labels. Whether you want to create custom product boxes, cards, or any other marketing material, we have covered everything related to die cutting, machines, techniques, methods, and expert tips. That will help you create an attractive personalized shape that you can’t create with a traditional method.

If you are looking to transform your packaging designs and take them to the next level, Custom Designs Boxes is here to help you out. We offer valuable die cutting services that ensure you will get customized and clean boxes or labels according to your preference.