Table Of Content

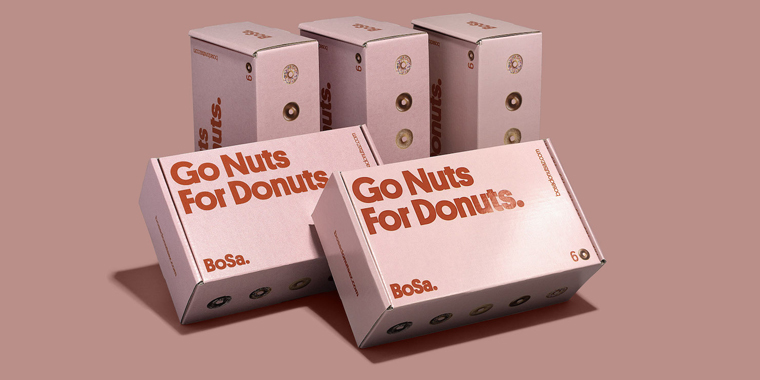

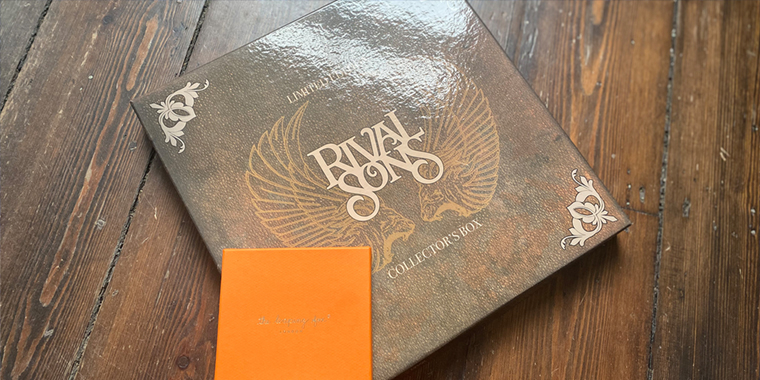

Packaging appeal and product quality are equally important. That’s why, every retail brand is striving to present its products with a luxurious touch. But in today's competitive market, standing out is quite a challenging task.

However, it can be done by packing your products in exclusive packaging that is either coated with gloss or matte lamination. Gloss lamination adds a shiny finish that draws attention and wows onlookers. While matte lamination vividly presents your products with a deluxe touch.

Each lamination has a unique texture, strength, result, and cost. Selecting the right lamination type is necessary to make the packaging that coincides with your brand preference and customers' interests.

This blog will give you insights into matte vs gloss lamination to help you choose the finish that maximize visual appeal of your products. Without further ado, let’s dive in!

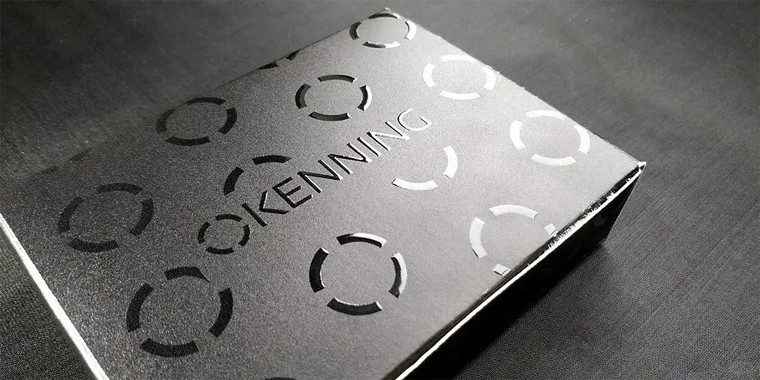

What Exactly is Matte Lamination?

Matte lamination is when a dull plastic film is applied to paper to give packaging a vivid look without extra shine. It is commonly used in packaging to enhance its presentation and strength. Matte lamination enhances printing results while making the packaging texture sleek and smooth. Therefore, it is called soft-touch lamination. In addition to boosting packaging charm, it maximizes packaging strength and makes boxes resistant to tearing.

Standout Benefits of Matte Lamination

Matte lamination makes packaging smooth and soft-touch. It also enhances packaging vibrancy and richness. Here are the unmatched benefits of matte lamination :

1. Vivid Appearance

Matte lamination enhances packaging readability, which is eye-grabbing. It enables your products to stand out and get huge sales instantly.

2. Anti-Glare Look

Matte lamination has a dull surface that makes it non-reflective in light. Display boxes with matte lamination do not dazzle in light while enhancing design recognition.

3. Improved Readability

A matte lamination is not reflective in daylight, which assists onlookers in reading and understanding the design.

4. Effortless Writing

Matte lamination provides ease in writing custom words. On matte laminate, you can write DIY notes, custom quotes, and taglines easily.

5. Multiply Packaging Strength

It makes packaging resistant and tamper-proof. Whether your packaging is in moisture or in daylight, matte lamination protects packaging from fading and tearing. Hence, it enhances its shelf life.

Where to Apply Matte Lamination?

Matte lamination is familiar for enhancing the aesthetic appeal of stationery items. Besides, you can also use matte lamination for:

- Luxury Jewelry Boxes

- Invitation Cards

- Book Covers

- Posters

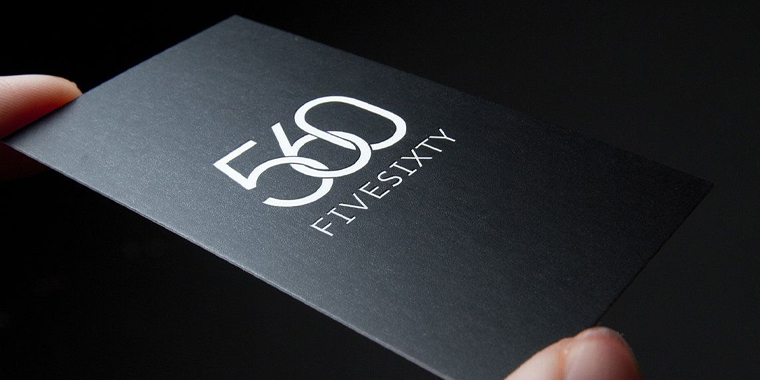

- Custom Business Cards

Disadvantages of Matte Finishes

When matte lamination is applied to packaging, it may mute one color and highlight another. It also minimizes color vibrancy, making your packaging dull and old. It causes lower packaging attractiveness.

Secondly, rust and dark spots become more visible on matte laminate, which spoils packaging designs. If you remove the matte sheet, it damages the printed designs.

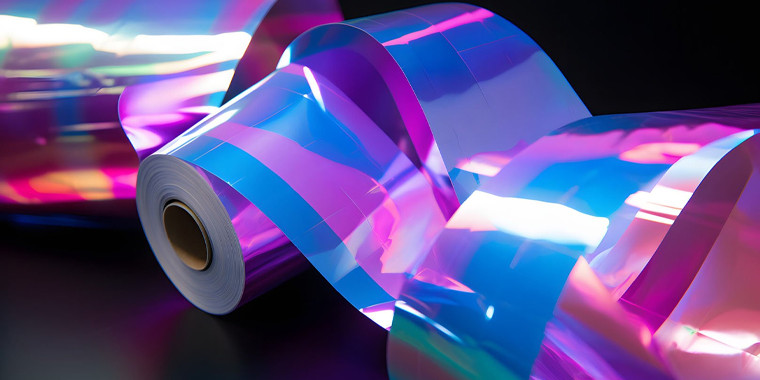

What is Gloss Lamination?

Gloss lamination is a transparent, shiny sheet. It gives luxury and a visually stunning appeal to packaging. It is fully reflective in light, multiplying color brightness. In addition to making your packaging prominent, it multiplies packaging strength and durability.

Outstanding Benefits of Gloss Lamination

Gloss lamination is used on packaging to make it shiny and enticing in appeal. It multiplies the color brightness and glamor of packaging. Below are the benefits of gloss lamination for packaging:

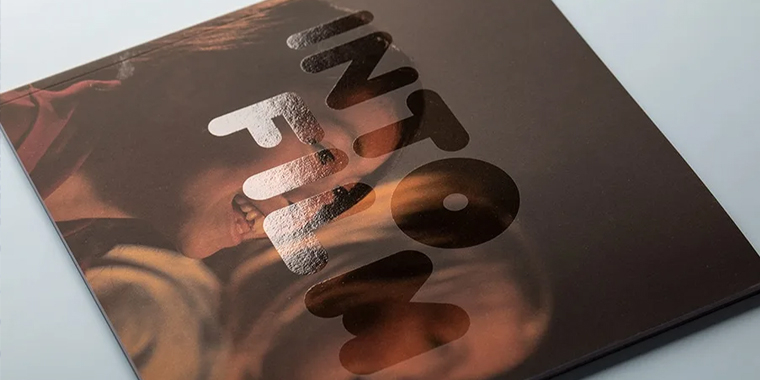

1. Add Glossy Impact

Gloss gives a royal look to packaging designs by adding an interfering and glittering touch.

2. Add the Chic Touch

It adds a luxurious touch while presenting your brand with a unique style. Hence, use it to show your professional creativity.

2. Enhance Packaging Strength

When gloss is applied to packaging, it makes it resistant to tearing and wearing out. It protects printed designs from dust, heat, smudges, and light.

3. Sunlight Protection

It adds a protective layer on packaging that protects the design from fading in light.

4. Easy to Remove

It is easy to peel out without damaging the packaging results and texture.

Where to Apply Gloss Lamination?

Gloss lamination is best for creating an enchanting and dazzling look. Some of the suitable places for gloss coating are:

- Luxury Gift Boxes

- Business and Postal Cards

- Magazines and Calendars

- Pleasant Stickers and labels

- Invitation Cards

- Photo Albums

Disadvantages of Gloss Finishes

In contrast to making your packaging attractive, gloss lamination has some cons. It adds unnecessary glare in light rays. Extreme shine makes the taglines and other branding elements difficult to read. Additionally, scratches and smudges also become more visible. It makes packaging slippery for handling and carrying.

Matte vs. Gloss Lamination: An Insight into Key Differences

|

Feature | Matte Lamination | Gloss Lamination |

| Look | Smooth and less shiny | Shiny and reflective |

| Texture | Velvety smooth | Smooth |

| Durability | Less durable | Highly durable |

| Sustainability | Eco-friendly | Less eco-friendly |

| Cost | Costly | Affordable |

| Place for Usage | For luxury packaging | For business letters and stationery |

Also Read: How Gloss Finishing On Boxes Leaves A Good Impact On Customers?

Final Words

Matte and gloss lamination are popular finishes. They are used to make packaging unique and durable. These not only enhance printing results but also make them high-strength. Gloss is for extra shine, whereas matte is for subtle design. Pick any finish that lies within your budget and truly aligns with your brand theme and style.

If you need affordable and high-quality matte or gloss lamination, then contact us at Custom Designs Boxes. We use our expertise to meet your specific needs within a low budget. Seek free design guidance from our ever-online customer support team. Send us an email at sales@customdesignsboxes.com to enjoy a free design consultation. Plus, Free Shipping for all throughout the USA and Canada.