Table Of Content

In the packaging and printing industry, the right finish can make a big difference. There are three coating types: matte, gloss, and spot UV. Spot UV is a popular coating technique that enhances designs with a high-gloss shine. It helps brands by providing protection and increasing the charm of their product packaging. With advancements in technology, this coating is easier to apply.

Businesses use spot UV coating on various packaging materials. That’s why knowing about this technique is beneficial for you if you are a business owner or want to be one.

In this blog, we’ll review spot UV coating in detail. Discover what spot UV printing is, how it works, and the factors to use it. Let’s begin!

What is Spot UV and How Does it Work?

In spot UV, a special coating is applied to specific areas of a printed surface. The coated areas are then cured using ultraviolet light. This hardens the coating and gives it a glossy, raised effect.

The technique can be used on different materials, including rigid and cardboard boxes. Spot UV is good for both light and dark backgrounds, but the contrast is more visible on darker surfaces.

The key to this printing technique is precision. A digital spot UV machine ensures that only selected areas receive the glossy coating. This leaves the rest of the surface with a matte or satin finish. It enhances logos and text for a professional look.

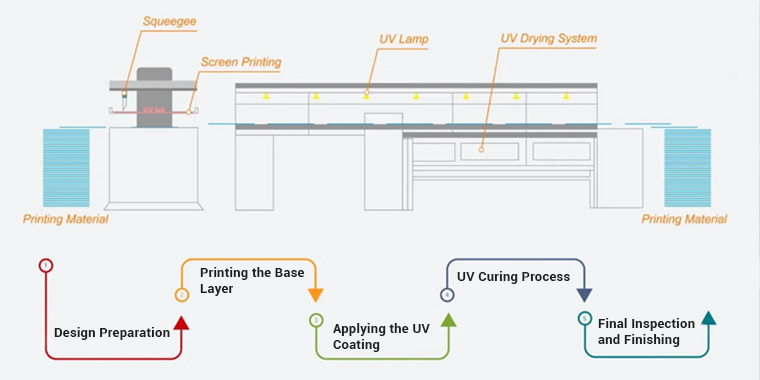

The Process of Spot UV Printing

Spot UV printing involves 5 steps to ensure a precise and high-quality finish. These are discussed below:

Step 1. Design Preparation

The artwork is created with designated areas marked for spot UV coating. These elements are usually separated into separate layers to ensure accuracy.

Step 2. Printing the Base Layer

The main design is printed using traditional offset or digital printing techniques. This creates the foundation for the application of spot UV.

Step 3. Applying the UV Coating

A clear spot varnish is applied only to the selected areas of the printed material. This coating is usually liquid before it is cured.

Step 4. UV Curing Process

The coated areas are exposed to UV light. It instantly hardens the varnish and creates a glossy effect.

Step 5. Final Inspection and Finishing

The printed material is checked for quality. Any additional finishes, like foil stamping, may be added.

Benefits of Spot UV Coating

Spot UV is widely used in packaging because it offers multiple benefits. Some of them are discussed below:

Spot gloss UV highlights specific elements in designs to provide a premium look.

- This coating protects against scratches and moisture.

- The contrast of matte and glossy areas creates a unique texture.

- It doesn’t contain harmful chemicals. That’s why it is a greener packaging alternative.

- It can be used on different materials, like luxury jewelry boxes and labels.

Applications of Spot UV in Packaging

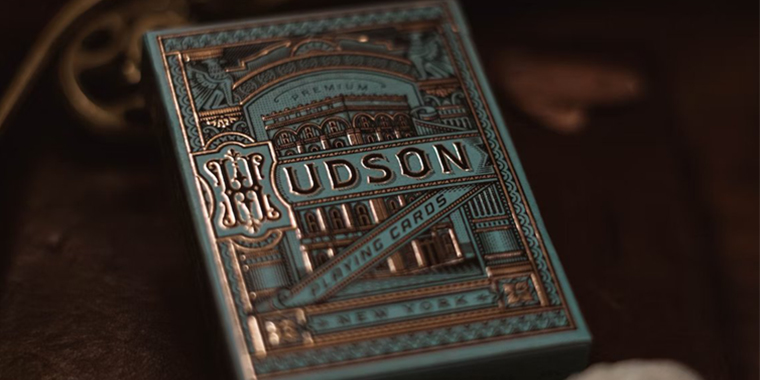

Spot UV is extensively used on business cards. These cards are known for their elegant appearance. The glossy effect highlights key details. This makes them more memorable. In packaging, this technique is used on boxes and custom mylar bags.

Embossed spot UV is a technique where the glossy effect is combined with embossing. It creates a raised, three-dimensional look. This is popular for luxury brands and cosmetics packaging.

Spot UV stickers are another application. These stickers have a high-gloss effect on specific areas. They add an extra layer of appeal to printed materials for promotional purposes.

Spot UV VS. Other Finishing Techniques

Spot UV is often compared to other finishing techniques. The key differences between spot UV and other techniques are as follows:

UV Coating VS. Spot UV

UV coating covers the entire surface with a glossy layer, while spot UV is applied only to specific areas for a contrasting effect, like on custom boxes with logo.

Spot UV VS. Embossing

Embossing creates a raised texture by pressing the material, whereas spot UV adds a glossy layer without changing the base material.

Spot UV VS. Raised Foil

A metallic foil is applied in raised foil stamping. This creates a shiny and raised effect. In contrast, spot UV achieves a glossy look without the use of foil.

6 Factors to Consider for Using Spot UV

Spot UV coating adds a premium touch to packaging, but several factors must be considered to achieve the best results. Let’s review them:

1. Material Compatibility

Spot UV works best on smooth surfaces. Uncoated materials may not hold the UV varnish well, leading to uneven application.

2. Design Elements

Using it on logos, text, or patterns can enhance visibility. The design must be carefully planned because excessive application can make the design look cluttered.

3. Contrast & Background Color

Blind spot UV stands out more against matte or dark backgrounds. Surfaces with light colors like white may not create as strong of a visual effect.

4. Cost Considerations

Spot UV is more expensive than standard printing finishes, so it should be used strategically. Businesses should balance cost with the desired impact.

5. Environmental Impact

Spot UV is more eco-friendly than solvent-based varnishes but can make recycling more difficult if applied in large areas. It helps to promote sustainable packaging.

6. Production Time

Spot UV requires additional curing and finishing time compared to standard printing. If a fast turnaround is needed, it should be kept in mind.

By considering these factors, brands can maximize the impact of spot UV while ensuring cost-effective and high-quality packaging solutions.

Also Read: How Spot UV A Prominent Coating Makes The Packaging Eye-Catching?

Wrapping Up:

Spot UV is a powerful finishing technique that enhances the visual appeal and durability of printed materials. It helps to grab customers’ attention. It is a favorite choice for luxury brands and businesses looking to create a premium look. This is because it can highlight specific design elements.

At Custom Designs Boxes, we offer customized packaging solutions that meet your requirements. Our professionals provide their expert insights to help you uplift your packaging game. Contact us via email today at sales@customdesignsboxes.com to outshine your competitors with our assistance.