Table Of Content

Coatings are a vital part of the packaging and printing industries. They increase the durability and charm of your packages. Aqueous coating is popular due to its protective and environmental benefits.

It offers a smooth finish and improves print quality. The life of packaging materials is extended using it. This type of coating is used for product packaging.

In recent times, green packaging has become a priority for businesses. Aqueous coating serves as a sustainable option in this regard.

In this blog post, we’ll learn about aqueous coating, its applications, and comparison with other techniques. So, why wait any longer? Let’s begin!

What Really is Aqueous Coating?

It is a coating in which a thin layer is applied to the packaging. It enhances colors with a smooth finish and protects against moisture.

You might wonder, “What is aqueous coating made of?” Aqueous ink is made from natural compounds that are derived from water.

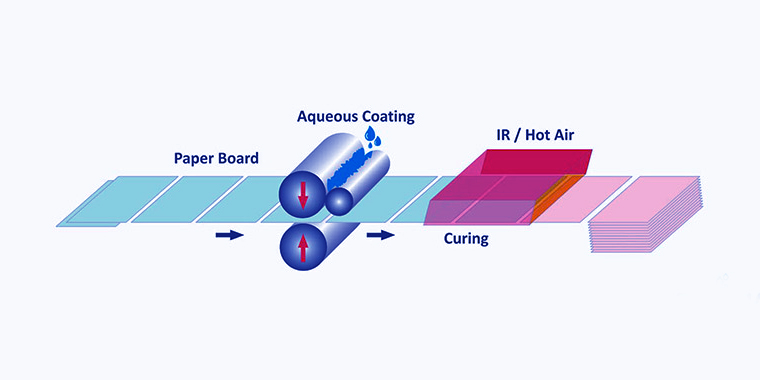

What is the Process of Aqueous Coating?

The process of applying aqueous coating involves 4 steps. These are discussed below:

Step 1. Preparation of the Solution

The solution is prepared using a formula. That contains water, polymers, and other additives.

Step 2. Application on Printed Material

The coating is applied using a coating unit attached to an offset printing press. The coating is spread evenly over the printed surface.

Step 3. Drying

The coating must be dried quickly for best results. The printed sheets pass through a hot air drying system. This evaporates the water content.

Step 4. Final Inspection

After drying, the sheets are inspected. If needed, additional processes like cutting or folding are performed.

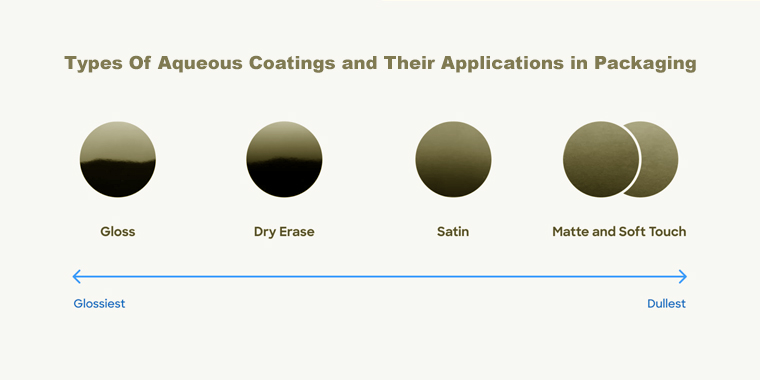

Types of Aqueous Coatings

There are numerous kinds of aqueous coatings, each serving a specific purpose. The most common ones include:

1. Gloss Aqueous Coating

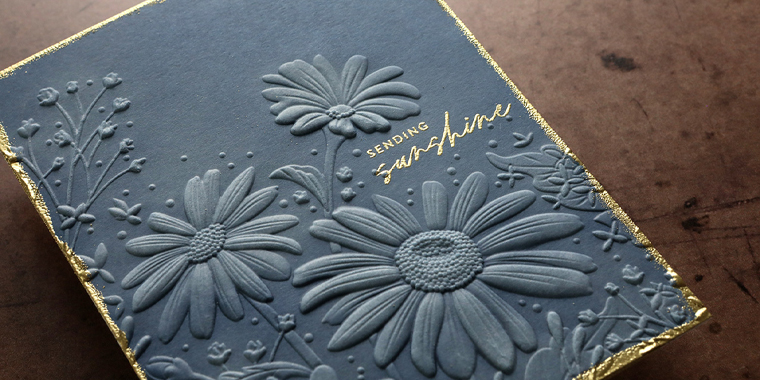

It makes colors appear more vibrant by offering a shiny finish. It is ideal to give a stunning appearance to packaging and other promotional materials.

2. Matte Aqueous Coating

This coating offers a non-glossy look. This reduces glare and creates a smooth texture. It is used for premium packaging, where an elegant finish is preferred. It gives a more sophisticated look to prints.

3. Satin Aqueous Coating

It offers a blend of gloss and matte. It doesn’t have excessive shine. It is used for custom business cards and luxury packaging. It provides a refined look with moderate protection.

4. Soft Touch Aqueous Coating

This coating provides a feel that resembles velvet. It is used by brands that need a premium unboxing experience. It makes your packaging enchanting for the customers.

Applications of Aqueous Coating in Packaging Printing

It is used for a wide variety of packaging materials. Some common applications include:

Business Cards

Aqueous coating business cards enhance durability and ensure they remain intact over time.

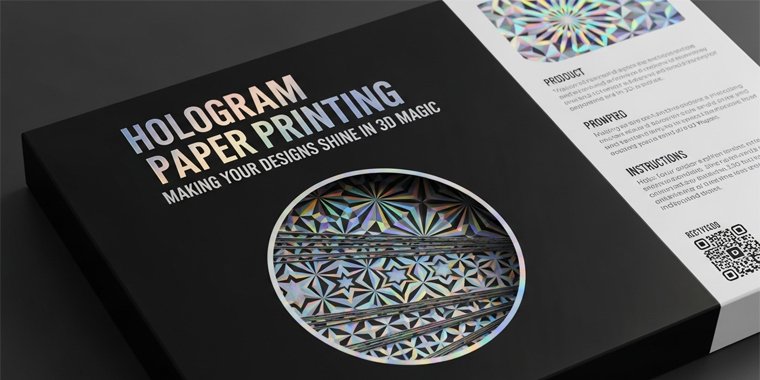

Product Packaging

Many brands apply this coating to their boxes to protect against it while maintaining a stunning look.

Aqueous Coating Paper

It is mostly used in magazines and booklets. This helps to improve readability.

Food Packaging

This coating is free from harmful chemicals. That’s why it is safe for food boxes. It prevents grease and moisture from affecting the packaging.

Aqueous Printer Compatibility

Most modern printers support aqueous coating, which makes them a cost-effective choice for bulk printing and packaging production.

Aqueous Coating VS. UV Coating

Both these enhance durability and appearance. Aqueous coating doesn't involve harmful chemicals, while UV coating uses chemicals.

UV coating is highly resistant to scratches and moisture. This makes it ideal for child resistant packaging. However, aqueous coating decomposes more easily and contains fewer chemicals. Due to this, eco-conscious brands prefer it.

In addition to this, aqueous coating is more flexible, making it suitable for packaging that requires bending.

What is the Difference Between Varnish and Aqueous Coating?

Varnish and aqueous coating differ in application. Varnish is solvent-based and requires more drying time. Aqueous coating is water-based and dries faster. It is more environmentally friendly.

Varnish becomes yellow over time, while aqueous coating remains clear for longer periods. Varnishes provide high gloss and superior protection. Aqueous coatings support excellent quality and sustainable packaging alternatives.

Can You Write on Aqueous Coating?

Writing on an aqueous-coated surface can be challenging due to its smooth finish. However, special pens such as permanent markers or specific ballpoint pens may work. If writing is required, a spot-coating technique can be used.

Some businesses go for hybrid solutions, combining aqueous coating with uncoated areas to allow for labeling. It is useful in packaging applications that require personalization, like waterproof labels.

Also Read: Varnish Coating: The Best Coating Solution For Your Brand’s Success

Final Words:

Aqueous coating is an essential part of modern packaging printing. It offers protection and enhances visual beauty. It also helps to promote sustainability efforts.

As businesses need greener alternatives, aqueous coating is a sensible option. At Custom Designs Boxes, we offer excellent packaging solutions that meet all industrial standards.

Our packaging keeps your products safe and grabs customer attention. Contact us today at sales@customdesignsboxes.com to get help from our experts to fulfill your packaging needs.