Table Of Content

Soft touch lamination is an amazing finishing option in the packaging industry. It provides a velvety feel that enhances the look and quality of printed materials.

This lamination is used for packaging boxes, business cards, book covers, and labels. It improves the aesthetics and adds a layer of protection to prints. Soft touch lamination is perfect for branding purposes as it creates an elegant impression.

Knowing about this lamination is beneficial for you if you are a business owner or planning to start one, as it helps in growing your business.

This blog post will discuss everything you need to know about soft touch lamination, including its benefits, applications, and comparison with other finishing options. So keep reading!

What Really is Soft Touch Lamination?

It is a finishing process where a special soft touch lamination film is applied to printed materials. This provides a soft, suede-like texture, which is different from gloss or matte lamination.

This coating reduces glare and offers a muted yet premium appearance. This lamination is commonly used for luxury packaging, premium business labels, and marketing materials that require a unique tactile experience.

Where is Soft Touch Lamination Actually Used?

Soft touch lamination is widely used in different industries. Some common applications are discussed below:

Luxury Packaging

It is used for premium product boxes and gift packaging.

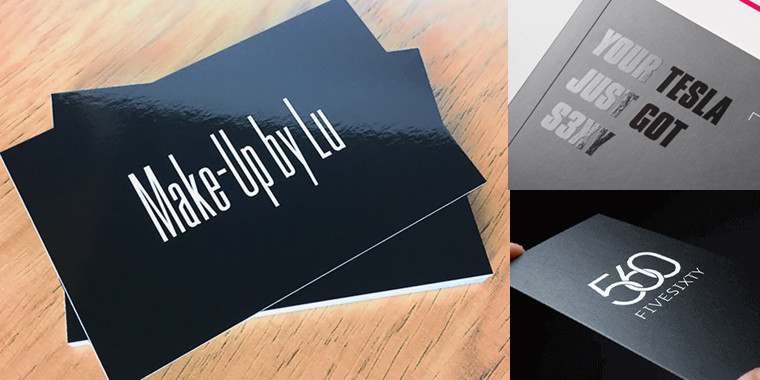

Business Cards

This lamination adds a high-end feel to custom business cards.

Book Covers

Soft touch lamination enhances the appearance and durability of books.

Labels and Stickers

It provides a smooth and high-quality finish for branding.

Brochures and Marketing Materials

This coating gives a refined look to printed promotional materials, like soft-touch laminating pouches.

Cosmetic and Perfume Boxes

This offers a sleek and soft finish for beauty product packaging.

Electronic Packaging

This finish is used for premium gadget boxes to improve customer experience.

How Soft Touch Lamination Works? 5 Simple Steps

The process of soft touch lamination involves applying a thin film over printed materials. Let’s find out how it works:

Step 1. Printing

The design is printed on high-quality soft-touch materials, like soft-touch paper or cardboard boxes.

Step 2. Lamination Film Application

A laminating film is applied using heat and pressure with a soft-touch laminating machine.

Step 3. Bonding

The film adheres to the surface. This creates a smooth and durable finish.

Step 4. Trimming and Cutting

The laminated sheets are cut to size for final use.

Step 5. Quality Check

The final product is inspected for a flawless finish.

Benefits & Drawbacks of Soft Touch Lamination

Soft touch lamination offers many benefits, but it also has some drawbacks. Let’s discuss them to understand it thoroughly:

Benefits

The velvety texture of this lamination enhances the overall sensory experience.

This finish gives a sophisticated and elegant appeal.

Soft touch lamination protects prints from scratches, moisture, and fading.

Soft touch coating deepens colors and makes designs more vibrant.

It is Ideal for high-end packaging that requires a refined touch, such as luxury apparel boxes.

This lamination doesn’t easily show smudges or fingerprints.

Soft touch lamination reduces glare, making it easier to read text.

Drawbacks

It is more expensive than standard matte or gloss laminations.

This lamination is durable, but it can get scuffed over time.

Soft touch lamination is not as moisture-proof as gloss lamination.

This coating requires extra processing, which leads to longer turnaround times.

Depending on the film used, soft-touch lamination may not be eco-friendly.

Soft Touch Lamination VS. Soft Touch Coating

Both soft touch lamination and soft touch coating create a similar smooth texture, but they differ in application and durability:

Soft Touch Lamination

A thin film is applied over the printed material in the case of soft touch lamination. This makes it more durable and resistant to scratches.

Soft Touch Coating

A liquid coating is spread over the surface and then cured. It offers a similar feel but less protection.

Cost Comparison

Soft touch lamination is usually more expensive but provides better longevity.

Flexibility

Coatings work better for flexible materials. While lamination is ideal for rigid boxes.

Comparing Soft Touch Lamination with Other Types of Lamination

Compared to other laminations, soft touch offers a distinct look and feel:

1. Gloss Lamination

It is shiny and reflective. This lamination enhances color brightness but lacks a soft texture.

2. Matte Lamination

It is smooth and non-glossy but not as velvety as a soft touch.

3. UV Coating

It provides a glossy finish with extra durability but no soft texture.

4. Aqueous Coating

It is a water-based alternative with eco-friendly benefits but less tactile appeal.

Is Soft Touch Lamination Right for You?

Soft touch lamination is perfect for brands that want to provide a luxurious impression. It works well for businesses that focus on exclusivity and high-end presentation. This is an excellent choice if you need packaging that stands out in terms of both look and feel.

Also Read: Gloss Or Matte Lamination Which Choice Is The Finest?

Summing Up

Soft touch lamination is a game-changer in the packaging industry. It enhances both visual appeal and durability while providing a premium tactile experience.

It provides a lasting impression for custom packaging products, such as luxury boxes, book covers, and many more.

At Custom Designs Boxes, we offer high-quality soft-touch laminated packaging solutions that are custom-made as per your requirements.

Contact us today via email at sales@customdesignsboxes.com to elevate your brand with our premium finishes.