Table Of Content

If you are related to the printing industry or own a business that needs packaging for its products, you've most probably heard the word “flexography," even if you don’t know its meaning.

Flexography is a type of printing that has changed the whole printing and packaging industry. It is popular because of the speed, efficiency, and versatility that it offers.

Flexographic printing has become the center point of the packaging industry as it is used in several sectors, such as the food, beverage, and pharmaceutical industries. Great results can be achieved on numerous materials like plastic, paper, and metals.

Is it a good choice for your business? Let's find the truth with this blog as it explores every aspect of flexography, including its benefits, step-by-step process, and applications.

What is Flexography Printing?

Flexography is the new version of the traditional letterpress technique. It uses raised image plates that are made of rubber or photopolymers to apply quick-drying ink onto the base.

This printing process is designed to be used on different types of materials, including uneven and flexible. It always provides consistent results. Due to this, it is the first choice for industries that require mass production, such as food packaging, label printing, and shipping containers.

Examples Of Flexography Printing

Flexography is highly versatile, which is why it is widely used in the market. Here are some examples of flexography printing:

- Retail Packaging: Attractive designs are printed on pouches for snacks and beverages with this type of printing.

- Labels: It is used to produce vibrant labels for jars and bottles for different industries.

- Gift Wrap And Wallpapers: Using flexography, patterns, and designs are printed consistently on a large scale. Flexography relies on specialized machines and plates to deliver consistent results.

Flexographic Printing Machines

Modern flexographic printing presses are categorized into three main types. These are described below:

1. Stack Press

Printing units are stacked vertically into this kind of press. It is suitable for flexible materials.

2. Central Impression (CI) Press

In the central impression press, the color registration is very precise, as it uses a single impression cylinder.

3. In-Line Press

Print units are arranged horizontally in this type of press. It is used with rigid substrates.

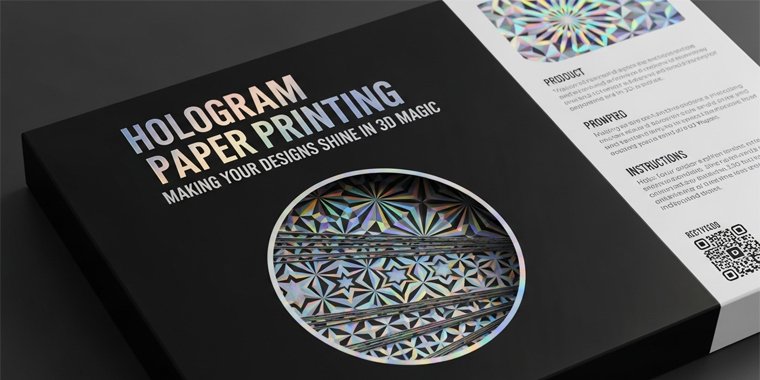

Flexographic Plates

Flexographic plates are made from durable photopolymers. These are designed to be operated at high speed to provide consistent results. These plates are reusable, which makes them cost-effective.

What are the Steps of The Flexography Printing Process?

Flexographic printing involves different stages to ensure precision and efficiency. The six steps of this printing process are explained below:

1. Plate Creation

The process begins with designing the plate. It is the heart of flexographic printing. Photopolymer or rubber plates are put under UV light to create raised areas. These plates are then washed and dried for future use.

2. Ink Selection and Preparation

Flexography uses inks that are based on water and solvents. These can also be cured by UV light. The viscosity of the ink is carefully adjusted for smoother application. These are selected as per requirements.

3. Ink Transfer Via Roll

A cylindrical roll engraved with microscopic cells is used in flexographic printing to transfer ink to a printing plate. It collects a certain amount of ink from the reservoir and transfers it to the printing plate.

4. Printing Process

The substrate passes through the printing press and the inked plate that is mounted on a cylinder makes direct contact with it. The flexible nature of the plate ensures even ink distribution on uneven surfaces, as well.

5. Drying and Finishing

After printing, the substrate goes through drying units. The heat helps the ink to cure quickly. If needed, additional steps are carried out to enhance the look and durability. Such as lamination or varnish.

6. Inspection And Quality Control

The final product is thoroughly inspected to ensure quality and consistency. Any issues are addressed before packaging and delivery.

Although the process is simple, understanding its advantages and disadvantages will provide a clearer picture of its popularity.

Advantages and Disadvantages Of Flexograph

Flexography has revolutionized the printing and packaging industry with versatility and efficiency. However, It comes with both strengths and limitations. Let’s explore the pros and cons of this printing type to find its suitability for your business.

Advantages

Flexographic printing is used in many industries due to the perks it offers. Some of them are described below:

1. Adaptable Material Use

It works on different types of materials, such as paper, cardboard, plastic, foil, and more.

2. Fast Production Speeds

This printing process is Ideal for high-volume printing as it has minimum downtime.

3. Cost-Effective For Bulk Orders

The setup costs are spread over large production runs. This makes it economical.

4. In-Line Processing

Additional operations like cutting and laminating can be done during printing. This makes the overall process convenient.

5. Eco-Friendly Options

It is environmentally friendly due to the use of water-based inks and a lower amount of waste.

Disadvantages

Apart from offering many advantages, there are also some drawbacks to flexography. These are:

1. Initial Setup Costs

Plate creation is expensive. Due to this reason, this process is less suitable for short runs.

2. Limited Detail

This kind of printing is great for bold designs, but it struggles with gradients and complex designs.

3. Deterioration

Plates degrade over time. That’s why they need to be replaced to maintain quality. Wondering if flexo printing is the best or offset.

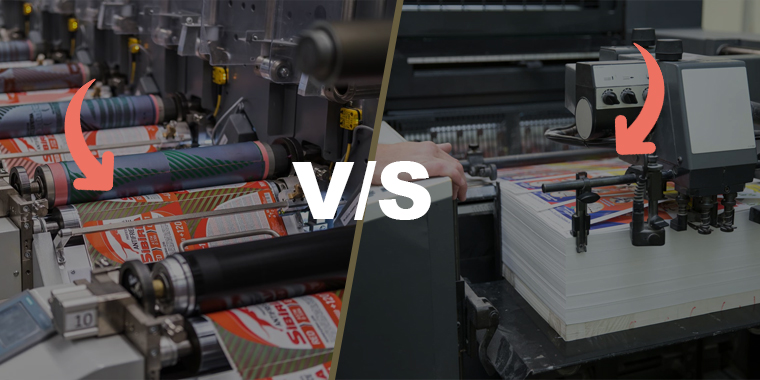

Flexography VS Offset Printing: Which Suits Your Packaging Business Best?

Although both these printing methods appear the same, they have many differences. These are discussed below:

| Feature | Flexography | Offset Printing |

| Substrates |

Works on porous as well as non-porous materials, such as cardboard and plastic. | Mostly used on flat and smooth surfaces like paper. |

| Production Speed | It has a faster setup and high speed for large-volume production. | It has a relatively slower setup but it is suitable for small-batch runs. |

| Print Quality | This is good for bold designs but limited in color gradients. | This is superior for detailed and color-accurate images. |

| Cost Efficiency | Economical for longer runs due to lower costs per unit. | Expensive for short runs due to the complicated setup. |

| Applications | Ideal for packaging, labels, and flexible materials. |

Best for brochures, magazines, and high-end printing jobs. |

This comparison clearly shows that flexo printing is the best for massive and high–speed production.

Applications Of Flexography Printing

Flexography offers versatility, which is why it is the ideal choice among different industries. Its adaptability with numerous materials and high-quality prints makes it perfect for the following applications:

1. Food And Beverage Packaging

It is widely used for printing on flexible materials like plastic films, pouches, and paper wrappers. The quick-drying inks make it suitable for items like snack bags, coffee pouches, and beverage labels.

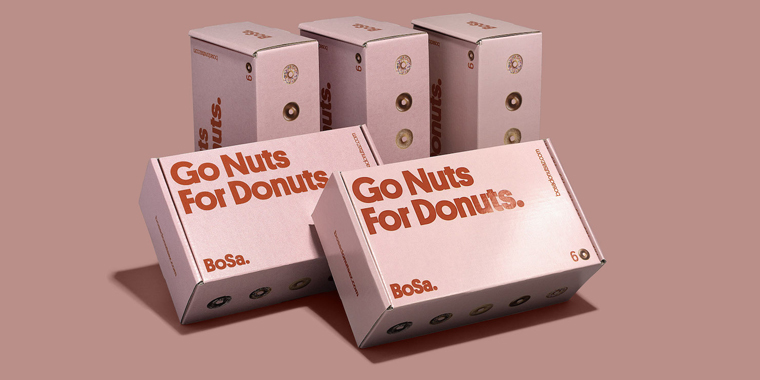

2. Corrugated Boxes And Cartons

Flexography succeeds in printing on corrugated materials that are commonly used for shipping boxes and retail packaging. Logos, branding, and essential information are printed directly onto the boxes, providing professional packaging.

3. Newspapers And Catalogs

Though digital printing has taken over some areas, flexography is still a popular choice for printed materials like newspapers, catalogs, and magazines. This is due to the high-speed production that flexography offers.

4. Pharmaceutical Packaging

Blister packs and other medicinal packaging need to comply with strict standards. Flexography ensures clarity and durability when printing essential information on the packaging.

5. Promotional Materials

Banners and other advertising materials mostly use flexography for bold and impactful designs. Promotion is essential for every business, which is why promotional materials are useful for all industries.

Factors To Consider When Selecting a Partner For Flexographic Printing

Choosing the right printing partner can bring a big difference in quality and efficiency. The following are key considerations in this regard:

1. Experience and Expertise

Look for a provider with a track record in flexographic printing across multiple industries.

2. Quality Assurance

Ensure the company has effective quality control processes to maintain consistency.

3. Technology And Equipment

Choose a partner that uses modern flexographic presses and advanced plate-making technologies.

4. Customization Options

A good partner should offer customized solutions for unique design and material needs.

5. Environmental Practices

Consider companies that prioritize eco-friendly inks and sustainable processes.

Is Flexography Printing Good for the Environment?

Every brand is shifting towards greener alternatives to carry out their operations. This is due to the trend of the consumer market, which is aimed at achieving the goal of a greener future.

Flexography printing is a sustainable option for packaging due to its efficiency and reduced environmental impact. The process minimizes waste by using quick setup times and efficient ink consumption.

Flexographic presses also consume less energy compared to other printing methods. Additionally, the materials used in flexo printing, such as films and papers, are recyclable. This supports eco-friendly packaging solutions.

Is Flexography Right for Your Packaging Business?

Flexography can be the best choice for your business if you need cost-effective printing at high speed for large volumes. It offers great color accuracy, sharp details, and quick drying.

It is most suitable for simple designs and to ensure consistency in your packaging. If your business requires complex designs and smaller batches, then other printing elements may be efficient.

Flexography is also the first choice for many businesses due to its applications on numerous kinds of materials. It can be used on both porous and non-porous surfaces.

Also Read: What is Lithographic Printing and How Does it Differ from Other Printing Methods

Wrapping Up

Hopefully, you have figured out if Flexo printing is good for your packaging business. It can benefit you with speed, versatility, and cost-effectiveness. This makes it a cornerstone in the packaging industry. It is applicable for producing food packaging, labels, or decorative items. Flexography provides reliable results for high-volume requirements.

At Custom Designs Boxes, we specialize in top-of-the-line flexographic printing customized according to your brand's needs. Partner with us to get vibrant and durable packaging solutions that help you to outshine your competitors. Contact us via email at sales@customdesignsboxes.com today!