Table Of Content

Wondering what is blister packaging? It is a type of packaging that offers a clear display of your products while keeping them safe. It provides convenience to the customers while enhancing the visual appeal of your product.

The innovative design of blister packaging helps businesses to outshine their competitors in the market. Blister packs are perfect for display purposes, and options like hangtops make it easier to offer your products to customers.

As a result, blister packaging has become a vital part of product packaging for many industries. In this blog post, we’ll find out about the types, materials, and applications of blister packaging. Keep reading to fulfill your knowledge bucket.

What is Blister Packaging

Blister packaging is a form of plastic packaging in which the product is covered with a plastic cavity (blister). This cavity is sealed from the back with some material (backing material). A normal blister pack consists of two main components:

1. Blister

It is a transparent cavity or pocket that is moulded from plastic for every product.

2. Backing Material

It can be a foil, paperboard, or plastic film, as per the requirement. They seal the product within the cavity.

Blister Packaging Examples

- Electronics and Accessories - USB drives and other small electronics.

- Stationery - Pens and other office supplies.

- Toys - Action figures and other toys.

- Cosmetics and Personal Care - Small items like lip balm and nail polish.

- Food Products - Small snacks and spices.

- Pharmaceutical Packaging - Medications or supplements.

Types of Blister Packaging

Blister packaging has many types. Some of the most common types are discussed below:

Face Seal Blister Packaging

This type of packaging is sealed to a card. It leaves the edges of the card exposed. It is used for lightweight retail products.

Full Card Blister Packaging

The plastic covers the whole surface of the card. This offers maximum protection and an elegant appearance.

Pharmaceutical Blister Packaging

It is designed for capsules and pills. These packs provide tamper resistance to pharma packaging.

Clamshell Blister Packaging

It has a design with hinges. It can be opened and closed multiple times. This is perfect for reusable items, such as small tools. Each type of blister packaging has a unique purpose.

5 Step Process of Blister Packaging

A precise process is followed to ensure product protection and visibility. Here’s how it works:

Step 1. Material Selection

A plastic film or sheet made from PVC or PET is chosen according to the requirements.

Step 2. Heating & Forming

The plastic sheet is heated and molded into cavities using a pressure-forming process.

Step 3. Product Placement

Items are securely placed into the formed cavities to keep them in place.

Step 4. Sealing

A backing material, such as foil, paperboard, or plastic, is heat-sealed onto the plastic.

Step 5. Cutting & Finishing

The sealed blister packs are trimmed into their final shape to make them ready for distribution.

Which Industries Can Use Blister Packaging?

Blister packaging is suitable for many industries. Here are some key applications:

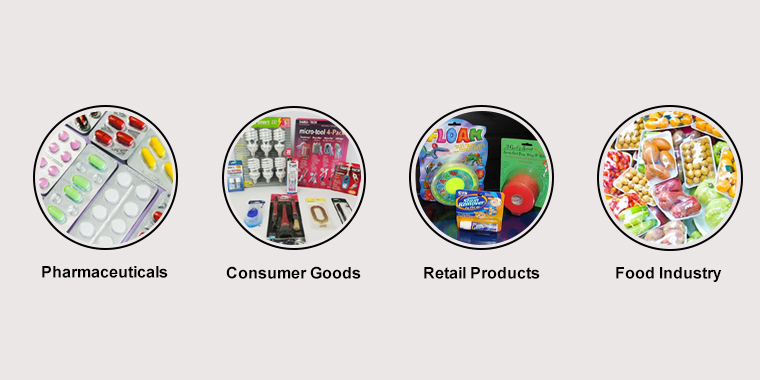

Pharmaceuticals

Blister packaging is used for pills, capsules, and medical devices. It provides resistance against tampering with pharma packaging.

Consumer Goods

This kind of packaging is ideal for small electronics, tools, and action figure packaging boxes.

Retail Products

It enhances the visual appeal of cosmetics, hardware, and accessories.

Food Industry

This packaging is ideal for single-serve items like gum and candies.

Healthcare

Blister packaging protects medical supplies from any contamination. These applications highlight the importance of blister packaging for different industries. Sustainable alternatives are also getting popular as industries are shifting towards greener options.

Benefits and Drawbacks of Blister Packaging

Blister packaging offers various benefits, but it also has some drawbacks. Let’s review them:

|

Benefits | Drawbacks |

| Shields products from contamination and damage | Not suitable for all types of products, such as liquids |

| Transparent blister showcases the product attractively | May require additional color labels for detailed information |

| Easy to use and track, especially for medications | Can be difficult to open for some consumers, like the elderly |

| Available in various shapes and sizes for branding purposes | Requires specialized equipment and processes |

| Eco-friendly options like PET are available | Traditional PVC-based packaging may not be recyclable in all regions |

By addressing these benefits and drawbacks, businesses can decide when to select blister packaging.

When to Choose Blister Packaging?

Selecting blister packaging for your product depends on several factors. These are as follows:

1. Product Type

If your product is small, lightweight, or sensitive to environmental factors, then blister packaging works best for such items.

2. Industry Requirements

To make sure that your packaging meets regulatory standards, blister packaging is a great option.

3. Branding Needs

If showcasing the product is necessary for sales, then the transparent design of blister packaging is perfect.

4. Budget

Consider the costs of materials and specialized machinery for blister card packaging.

5. Sustainability Goals

Go for recyclable materials like PET if eco-friendliness is your priority.

Wrapping Up:

Now that everything is clear about what blister packaging is? We know it serves as a pillar for modern packaging solutions, as it offers unmatched protection, visibility, and convenience.

From pharmaceutical products to retail items, its applications are vast and ever-evolving. At Custom Designs Boxes, we specialize in creating high-quality, customized blister packaging that meets your specific needs.

If you are looking for sustainable solutions or innovative designs, our experts are here to help. Contact us today via email at sales@customdesignsboxes.com to explore how blister packaging can enhance your brand’s presence in the market.