Table Of Content

Lithography is one of the most popular printing techniques due to the versatility it offers. It has traditional roots, yet it is evolving continuously with modern advancements.

It is used in various industries, ranging from packaging to art reproduction. So, if you are a business owner or related to any industrial sector, knowing about this technique is important for you.

This guide will help you in this regard as it explores lithography, explaining its process, applications, advantages, and how it compares with other printing methods. So, without any further ado, let’s start our journey!

What Is Lithography Printing?

Lithography is a planographic printing technique. In this technique, the printing and non-printing areas exist on the same flat surface. The magic is in the principle that oil-based ink repels water. This ensures that ink adheres only to the image areas.

History

Lithography printing was discovered by Alois Senefelder in 1796. He found a way to efficiently reproduce theatrical scripts. With time, it evolved into offset lithography. It became the cornerstone of mass printing in the twentieth century. Even today, innovations like digital lithography printing and 3D lithography enhance its scope.

Examples

This printing technique is used extensively in the market. Some real-life examples where lithography makes an impact are as follows:

- Premium Packaging: It is used on the boxes of luxurious products that have complex designs, like luxury jewelry boxes.

- Artistic Prints: Lithography printing is used in limited edition lithographs for art lovers and collectors.

- Marketing Collateral: This method is used for posters, brochures, and brochure display holders.

Applications

Lithography printing is widely used in different industrial sectors. Some of them are described below:

Product Packaging:

It is ideal for printing vivid logos and designs on boxes, cartons, and packaging labels.

Books And Magazines:

This printing technique is perfect to ensure consistency, in case of large volume prints that require high-quality results.

Advertising Materials:

It is used for posters, brochures, and flyers to showcase sharp images and vibrant colors for e-commerce packaging.

Art Reproduction:

It allows artists to create detailed artwork with exceptional clarity.

Advantages and Disadvantages

Lithography has many perks due to its diverse applications. Let’s discuss them for better understanding.

Advantages

Lithography offers high-definition printing and consistent results. Let’s review its other benefits, as well:

- Exceptional Quality: It produces sharp images due to the consistent reproduction of colors.

- Cost-Effective For Large Runs: It is the best option for bulk printing, as it significantly reduces per-unit costs.

- Versatile: It is suitable for many materials, including paper, white cardboard boxes, and some plastics.

Disadvantages

Without a doubt, lithography offers numerous advantages, but it also has some drawbacks. Some of them are described below:

- Setup Costs: The initial costs for plates are high. This makes it less suitable for small runs.

- Longer Turnaround: The setup process is more time-consuming, as compared to digital printing.

- Environmental Impact: As chemicals are used in this process, they can affect the environment badly without proper disposal practices.

Now that you know the basics of Lithography printing, Right? Let’s keep up the pace and discuss its printing process.

The Printing Process Of Lithography

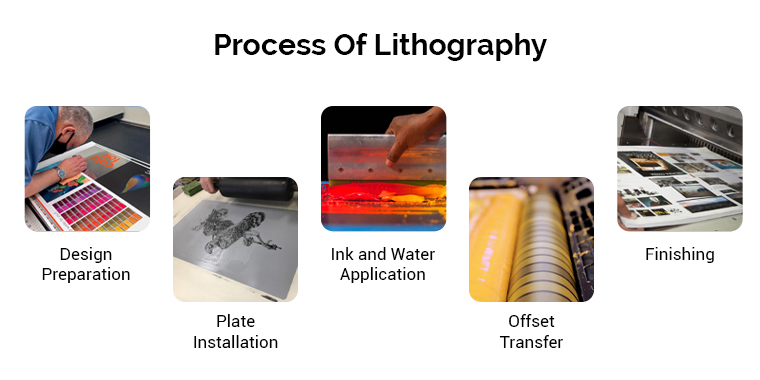

The Lithographic printing process is a stepwise procedure that is designed to ensure precision and quality. Let’s find out how:

1. Design Preparation:

Images or text are prepared on a plate using a chemical process that makes the design areas ink-friendly and non-design areas repellent to ink.

2. Plate Installation:

Then, the plates are mounted onto the printing press.

3. Ink and Water Application:

A mixture of water and oil-based ink is applied to these plates. Water adheres to non-image areas, while ink sticks only to the image areas.

4. Offset Transfer:

The inked image is transferred to a rubber blanket before being applied to the substrate. This is to ensure consistent and accurate results.

5. Finishing:

Lamination or varnish is applied after printing to increase the durability and aesthetic appeal of the product. After discussing lithography printing in depth, let’s compare it with other printing techniques.

Lithography VS Other Printing Techniques

Lithography stands out in the printing world, but understanding its differences compared to other techniques can help determine when it’s the best choice.

Lithography stands out in the printing world, but understanding its differences compared to other techniques can help determine when it’s the best choice.

|

Feature |

Lithography Printing |

Digital Printing |

Screen Printing |

|

Best For |

High-volume projects and detailed designs |

Short-run jobs and fast production |

Textiles and irregular surfaces |

|

Material Options |

Paper, cardboard, plastics |

Paper, cardstock |

Fabric, glass, ceramics |

|

Cost Efficiency |

High for bulk orders |

Moderate for smaller projects |

High setup costs for small runs |

|

Print Quality |

Superior and consistent |

Good for small runs |

Moderate for fine details |

|

Sustainability |

Moderate, as it uses some chemicals |

High, due to eco-friendly options |

Depends on the choice of ink |

This is considered the era of advancement, so let’s not forget about the exciting innovations in lithography printing.

Modern Innovations In Lithography

The evolution of lithography includes technologies like digital lithography printing and 3D lithography. These advancements help to streamline processes and enhance precision. They also allow the application of eco-friendly practices and reduce waste. Selecting the right partner for lithographic printing is crucial. With this in mind, let’s discuss different factors for an ideal partner.

Also Read: Is Flexography Printing the Best Choice for Your Business?

Factors to Look For in Your Lithographic Printing Partner

When selecting a lithography printing partner, consider the following factors:

- Industry Experience: Choose a company with proven expertise in lithographic techniques.

- Technological Capabilities: Ensure they use advanced lithographic printing machines for their operations.

- Sustainability Practices: Look for providers that offer greener alternatives by using eco-friendly inks and materials.

Look for providers that offer greener alternatives by using eco-friendly inks and materials. There are many brands out there that fall under these criteria, and we are one of them. At Custom Designs Boxes, we combine modern technology with years of experience to deliver premium lithography printing solutions that are made according to your needs.

So, why wait any longer? Contact us via email today at sales@customdesignsboxes.com to set yourself apart from others in the market with our assistance. In the end, let’s address some frequently asked questions to provide a deeper understanding of lithography.