Table Of Content

Packaging is the first point of contact between your brand and the customers. That’s why your packaging must be top-notch to outshine your competitors in the market. To make this happen, embossing and debossing are two of the most effective printing methods. These techniques add texture & depth to your packaging and increase its visual appeal.

Want to uplift your packaging game with high-end printing? Worry not! You are in the right place, as this guide will help you make the best decision. We will explore how Emboss Vs Deboss in depth.

What is Embossing?

Embossing is a technique in which a design is raised above the surface of the material. It creates a 3D effect. This method is widely used to highlight logos, text, or patterns. It gives them a premium look and makes products more engaging and memorable.

Types of Embossing Techniques

Several kinds of embossing are available in the market. Let’s discuss some of them which are widely used:

1. Blind Embossing

This technique uses no ink or foil. It focuses on the raised design to strike an impression. Blind embossing is ideal to add a touch of elegance. For example, a minimal logo embossed on a matte box provides a sophisticated look.

2. Registered Embossing

It aligns the embossed design with printed elements to add details. This offers visual and physical harmony. For instance, text highlighted with embossing on branded stationery boxes offers a professional look.

3. Combination Embossing

Embossing is combined with foil stamping in this technique for a luxurious effect. The combination of textures and colors makes designs stand out. For example, metallic logos on high-end product packaging create a premium vibe. This is perfect for luxury gift boxes.

How Does Embossing Work?

The process of embossing consists of three steps. These are discussed below:

Design Preparation:

A metal die is created according to the desired design. Precision in die creation ensures high-quality results.

Material Selection:

Paper, cardboard, or leather are common materials for embossing. Each of them offers unique qualities.

Pressing:

The material is pressed between the dies, which provides a raised design. This step requires extreme caution to get consistent results.

Advantages & Disadvantages of Embossing

The embossing technique offers many advantages but also has some disadvantages. So, let’s take a look at them:

Advantages

- Add a sensory element and increase the visual charm.

- Create a sense of exclusivity and enhance the perceived value.

- The embossed impressions are resistant to wear and long-lasting.

Disadvantages

- The detailed process and specialized tools can be expensive, making it less suitable for new startups.

- Work best with specific materials, limiting its versatility.

- Difficult to maintain consistency of colors on raised areas.

What is Debossing?

Debossing is the opposite of embossing. It involves creating an indented design on the material. It presses the design below the surface. This technique is subtle but impactful. It is normally associated with minimalism.

Types of Debossing Technique

Different kinds of debossing are available in the market. Let’s discuss some of them:

1. Blind Debossing

No ink or foil is used in this type of debossing. It solely focuses on the indentation. This simplicity calls attention to texture. For example, a pattern debossed on leather journals adds elegance to everyday items.

2. Registered Debossing

It aligns the debossed design with printed elements to provide symmetry to your packaging. For instance, branding on luxury boxes ensures that the logo complements the overall design.

3. Foil Debossing

This technique combines debossing with foil stamping for an elegant look. The shimmering effect of foil is perfect to attract customers. For example, debossed logos on holographic foiling boxes communicate a sense of exclusivity.

How Does Debossing Work?

The process for the debossing technique has three steps. These are described below:

1. Die Creation

A metal die is made according to the design. Accuracy ensures clear and sharp indentations.

2. Material Selection

Materials such as paperboard or plastic are commonly used for this technique. These are chosen for their adaptability.

3. Pressing

The material is pressed into the die. It creates a recessed effect and adds depth to your packaging.

Advantages & Disadvantages of Debossing

Look at the table to get a clear idea of the advantages and disadvantages of debossing.

Advantages

- Ideal for minimal and elegant designs.

- Suitable for various materials and design styles.

- Designs remain intact as they are resistant to damage.

Disadvantages

- May not stand out on certain materials or colors.

- Complex designs can increase production costs.

- Time-consuming, especially for large quantities.

Emboss Vs Deboss: A Comparison of Key Features

You may wonder, “Is debossing the same as embossing?” No, It’s not the same. Look at the table to analyze the key differences.

| Feature | Embossing | Debossing |

| Appearance | Raised design | Indented design |

| Visual Impact | Bold and prominent | Subtle and understated |

| Material Compatibility | Paper, white cardboard boxes, leather | Paper, plastic, leather |

| Cost | Generally higher | Slightly lower |

| Use Cases | To highlight logos, titles, patterns | For minimalist branding on backgrounds |

Embossing and debossing provide different effects but enhance the aesthetic appeal of packaging.

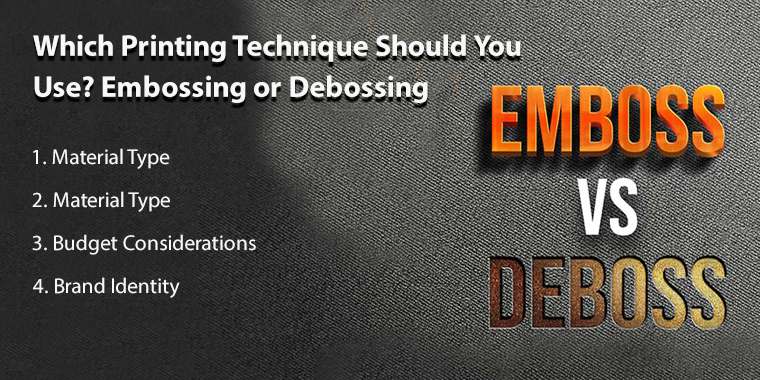

Which Printing Technique Should You Use? Embossing or Debossing

When selecting embossing or debossing, several factors come into play. These are described below:

1. Design Goals

Embossing is ideal if you want bold and eye-catching designs. On the other hand, debossing provides elegance, which is suitable for minimalist branding.

2. Material Type

The compatibility of the material with each technique is important. For example, embossing works exceptionally well with rigid materials and magnetic closure boxes, while debossing adapts to a broader range.

3. Budget Considerations

Embossing typically involves higher costs, as compared to debossing. This is due to the raised design and intricate dies.

4. Brand Identity

Use the most suitable technique to meet the expectations of your target audience. Both these techniques can also be used simultaneously for your premium packaging.

Wrapping Up!

Our roundup is over for emboss Vs. Deboss. Right? We have come to the conclusion that both of these techniques can uplift your packaging game. So, if you are looking for custom designs packaging to integrate these techniques conveniently, we can assist you in this regard.

Our experts provide perfect embossed or debossed printing results according to your requirements.

With customizable designs and greener materials, we help you create packaging that leaves a lasting impression. Our commitment to quality ensures that your packaging turns your brand’s vision into reality. Contact us today via email at sales@customdesignsboxes.com to elevate your brand with our customized packaging solutions.