Table Of Content

Debossing is a decorative technique used to imprint or press a design into the surface of a material, producing a recessed, 3D look. It is a component of typographic finishing and dry printing. You can consider it a popular option for brands aiming to impart a refined and everlasting impression on promotional products because of its nuanced beauty. Debossing gives items like notebooks, portfolios, and other business gifts a polished look. It is frequently applied to materials like leather, faux leather, certain types of plastic, and thick paper.

Still wondering what is debossing? In order to help businesses determine whether debossing is in line with their branding objectives, this guide will cover the procedure, pros and cons, best types of products, and suitable materials for debossing, as well as a comparison with other decoration techniques.

How Debossing Works

Making a particular metal die and pressing it into the selected material to create a clean, recessed imprint is the first step in the debossing technique. Bronze dies are typically used in hot foil stamping because of their weight and strength, which allow for more powerful and accurate pressure. To achieve a flawless finish, this tricky engraving technique requires precision, modern equipment, and careful material selection.

Most importantly, pressure control is paramount during the paper compression stage. An excessively deep impression made with too much force may result in surface irregularities. This increases the chances of air bubbles forming when labels are later applied to the products, ultimately sabotaging the overall presentation.

The Debossing Process Step-by-Step

1. Designing and Creating the Die:

To stand up to the pressure used during debossing, a custom die or mold is made based on the pattern and is typically made of metal.

2. Aligning the Die and Material:

The die is placed at the specified spot on the material. To guarantee that the design looks exactly as envisioned, accurate alignment is necessary.

3. Applying Heat and Pressure:

To create a sunken impression, the die is then firmly pressed into the material. Heat is used on some materials to guarantee a clear and durable impression.

4. Finishing Touches:

A neat, recessed design is the outcome of removing the die. For a better look, optional details like foil stamping can be applied.

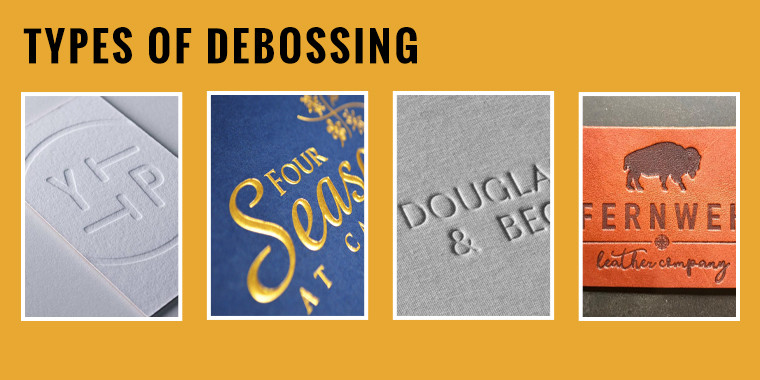

Types of Debossing

Depending on the desired visual impact and branding, debossing printing can be done in a variety of ways. Every method produces an exceptional finish, which lets companies get the right look and feel they seek.

Blind Debossing

This is the most basic process, in which the design is pressed into the material without the use of foil or additional color. It is perfect for premium, minimalist branding and makes an uncluttered and discreet impression.

Foil Debossing

Here, the recessed design is filled with coloured or metallic foil, producing an intriguing contrast. For businesses that desire texture and a splash of color, like holographic, gold, or silver, this approach is ideal.

Registered Debossing

Using this method, the printed artwork and the debossed impression line up beautifully. By bringing depth and attention to detail, it improves flat printing and gives typography and logos a more luxurious, fancy appearance.

Heat Debossing

To guarantee that the die leaves a deeper and sharper etching, heat is utilized in addition to pressure. It works particularly well on leather and synthetic textiles, promising long-term durability and vibrancy.

Pros and Cons of Debossing

It has benefits and drawbacks, just like any decorating technique. Here's a closer look to assist companies in considering their alternatives.

|

Advantage | What It Delivers |

| Long-Lasting, Wear-Resistant Design | Even after repeated handling, the etched imprint remains pristine, guaranteeing that branding stays crisp and attractive over time |

| Premium Vibe | Produces a subtle touch that is perfect for business branding, executive gifting, and luxury goods. |

| Impressive Tactile Experienceq | Promotes a product's memorability and bolsters a brand's credibility by adding tangible depth and texture. |

Businesses can decide whether debossing is the best option for their promotional items and if it fits with their branding goals by being aware of the list of limitations mentioned below.

|

Limitation | Consideration |

| Material Restrictions | It is not appropriate for thin or flexible materials, since it works optimally on materials that can retain their shape, such as thick paper, leather, and synthetic leather. |

| No Built-In Color Application | Debossing by itself produces a textural appearance devoid of color; foil, ink, or other techniques must be used to lend a sense of contrast. |

| Higher Upfront Setup Cost | For very short production runs, custom die creation is less cost-effective because it requires a larger initial investment. |

Types of Materials Compatible with Debossing Printing

Materials that can maintain their own distinctive look without losing their structure are ideal for debossing. Because every material responds differently to the pressure and heat applied, choosing the appropriate material is key to getting the greatest debossing results.

Both real and synthetic leather are suitable since they are long-lasting, making them ideal for expensive promotional goods and corporate presents. Additionally, for business cards, invitations, and personalized packaging, thick paper and cardboard are engraved to lend a formal look. Furthermore, some plastics can be debossed, but specific tools or dies may be needed.

Products Best Suited for Debossing

On the one hand, wallets, notebooks, and folders are often debossed for a classy look. The engraved logo makes a sharp impression when these items are given as corporate gifts. On the other hand, the debossed style is perfect for takeaways and gifts like baggage tags and keychains because it discreetly draws attention to the brand without overriding the product's appeal.

Debossing makes business cards and invites stand out considering that it gives the design richness and an enjoyable feel while underlining a brand's attention to quality.

Additionally, debossing works better on unprinted, pure paper because the result is more noticeable. Doing so gives the debossing the possibility to come out - thanks to the lights and shadows created by the slight depth.

Caring for Debossed Products

Besides learning debossing meaning, let's dive into something deeper!

The physical and aesthetic appeal of debossed promotional items can be preserved with proper care, guaranteeing that consumers will find them pleasant and useful.

Prevent Overexposure to Sunlight:

Extended exposure to direct sunlight can cause leather or faux leather materials to yellow out, which could affect the debossed design's appearance. When possible, keep debossed objects out of UV rays.

Gentle Cleaning:

Use a type of mild cleanser made especially for leather and faux leather products. Steer clear of harsh or abrasive chemicals as they can harm both the etched impression and the material.

Keep Dry and Condition Leather Items:

Over time, moisture can cause leather to weaken. To preserve the flexibility and beauty of debossed leather goods, keep them dry and think about conditioning them on occasion.

Store Properly:

Debossed goods should be kept dry and free of dust when not in use. Notebooks and wallets can be protected from wear and tear by using a soft cloth bag.

Is Debossing Right for Your Brand?

Debossing is a great choice for companies who want their promotional materials to be fashionable, long-lasting, and discreet. This method works well for giving materials like leather, faux leather, and thick paper an upscale appearance, which makes it ideal for corporate presents, luxury goods, and simple patterns.

It is a practical and powerful solution for companies looking to give their promotional products a high-end finish. Get in touch with Custom Designs Boxes to discuss debossing possibilities for your upcoming project.