Table Of Content

Nowadays, the two main frame printing techniques are used to make the custom packaging branded, promoting, and interesting. These are embossing and debossing.

These custom packaging techniques not only add visual appeal but also create an experience that enhances tactile branding, making your product irresistible to customers.

Embossing gives a 3D upward feel and debossing gives a downward design with a 3D fee. These both are used for a sophisticated and high-end feel, so understanding the distinctions and advantages of both embossing and debossing is essential.

Knowing which technique to choose can significantly impact how your packaging reflects your brand. Their right use is crucial and can impact a lot on users' behavior and product perception.

Let us dive into the debate.

What is Embossing?

Embossing is a printing technique in which a metal die is pressed into a material, such as paper or packaging, to create a raised, 3D image or text.

Embossing is commonly used for logos, designs, or patterns. It adds texture and a luxurious feel to the surface of the material. Plus, it enhances its visual appeal and tactile experience.

Embossing Process for Custom Packaging

The embossing process is simple. At the start of the embossing process, a metal plate known as a die is created. A die is a raised image on the plate that you want to emboss onto the final product.

The die presses into the stock, gently raising images on the paper or your print piece. A single-level die raises your image to a single consistent height or depth, whereas a multi-level die creates a more complex emboss or deboss.

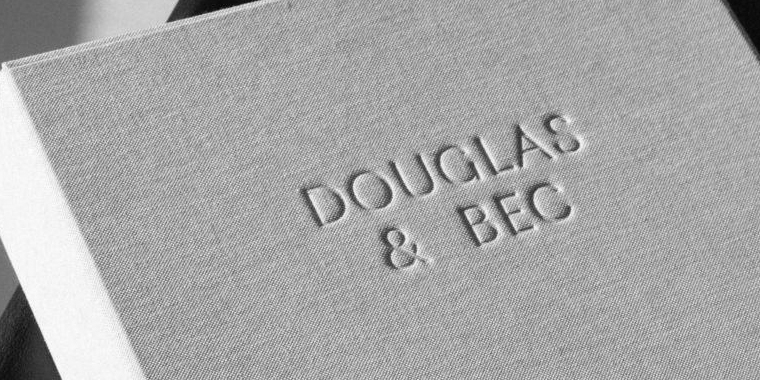

To achieve a luxurious effect, companies frequently emboss their logo, bespoke illustrations, initials, or patterns.

It’s important to note that embossing a logo is different from raised ink printing, known as thermography. Embossing physically alters the paper’s shape, whereas thermography uses a special powder that binds to the paper when heated.

Although embossing is a costly process, the quality is undeniable, providing a touch of refinement and exquisite feel to finished custom packaging designs.

Top Advantages of Embossing for Your Brand

Why do people use embossing? Here are the reasons why embossing is still the top choice for brands.

It creates a 3D Design. Embossing produces a 3D design that prominently stands out from the surface.

Plus, it has enhanced foil stamping features. Applying foil stamping is easier on an embossed design. It gives more vibrant and detailed finishes.

It has finer detail accommodation. Embossing can accommodate finer details compared to debossing. It is ideal for intricate logos and designs.

It has versatile applications. It is better suited for personalized stationery, business cards, and other paper promotional items.

What is Debossing?

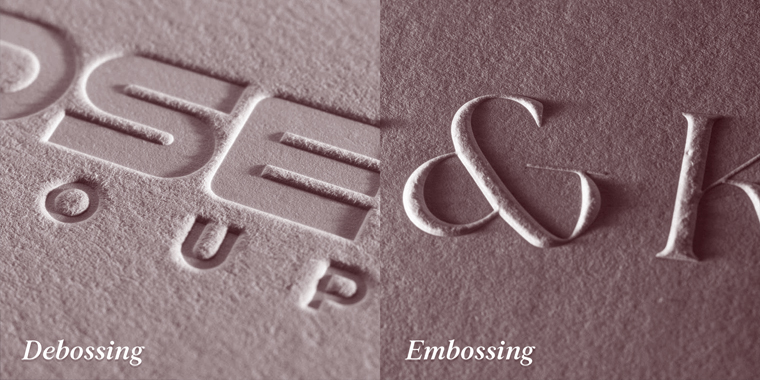

Debossing is a process similar to embossing, but instead of raising the design, the die presses the design into the material, creating a sunken or recessed effect.

It is often used on leather, paper, and packaging to add depth and a subtle, elegant touch to designs.

Debossing Process Explained

The debossing procedure mirrors embossing but instead of pushing the design outward. The die presses the logo downward into the material, creating a recessed effect. While debossing is not as popular as embossing, it offers a distinct aesthetic that conveys subtle elegance.

Key Benefits of Debossing in Packaging

Debossing gives numerous benefits for packaging and printing such as adding dimensional depth, preserving material integrity, affordability, and many others.

Debossing introduces a layered depth to the design, enhancing visual interest. Plus, applying ink to a debossed design is more straightforward, ensuring even coverage.

Moreover, a debossed design does not affect the backside of the material, maintaining its structural integrity. One of the notable things is that debossing plates and dies are typically less expensive than embossing plates and dies.

And the last benefit is it is Ideal for Leather Accessories. It is best suited for personalizing wallets, portfolios, briefcases, luggage tags, and other leather items.

Embossing vs Debossing: Key Differences

What is the difference between embossing vs debossing? You would have gone through many articles with title emboss vs deboss, but the key differences between them are given here in the simplest form.

| Feature | Embossing | Debossing |

|

Design Effect |

Raised, 3D appearance |

Indented, sunken appearance |

|

Material Impact |

Pushes material outward |

Presses material inward |

| Usage |

Standout visual effects, luxury items |

Subtle, sophisticated designs |

| Cost |

Generally higher due to intricate dies |

Typically lower, less intricate dies |

Factors to Consider When Choosing Between Embossing and Debossing

Not all images are suitable for embossing or debossing. Investing extra time and resources upfront ensures your project is executed correctly, saving money and time in the long run.

Here are the key considerations before incorporating embossing or debossing into your printed design.

Begin With Vector Art

Request that your designer provide the final design as a vector art file rather than a raster one. Vector art can be resized without losing quality, ensuring the best conversion into an embossing die.

Select the Best Part of Your Design to Emboss

Embossing works best with text, logos, single images, initials, and simple patterns. It’s most effective as an accent rather than covering the entire design. For example, a repeated pattern on a business card can add a classy touch without overwhelming the design.

Prefer to Use Heavier Paper Stock

To highlight the depth and intricacy of embossed graphics, use heavier paper stock. For multi-level embossing, ensure that the deepest regions of the design are larger to prevent tearing.

Combine with Foil and Other Techniques

Embossing and debossing are often used alongside other creative techniques like foil stamping, varnish, or film lamination. When combined with foil, embossing should be performed concurrently to ensure perfect registration between the relief and the foil.

Best Practices for Embossing and Debossing

Here are a few things you must consider while using embossing or debossing.

You must ensure your design is suitable for embossing or debossing by keeping it simple and avoiding intricate details that may not translate well.

For better embossing or debossing procedures, work with Experienced Printers. Collaborate with printers who have expertise in embossing and debossing to achieve the best results.

Always request samples before final production to ensure the embossing or debossing meets your expectations.

Ensure that embossing or debossing complements the overall packaging design and aligns with your brand’s aesthetic.

Final Words

Now that you understand the key differences and advantages of embossing and debossing, it's time to make a decision that best suits your brand's vision. If you're aiming for a bold, elevated look, embossing can help your packaging stand out on store shelves.

Alternatively, if subtle elegance is your goal, debossing adds depth and refinement. Either way, both techniques offer unique ways to enhance the appeal and functionality of your packaging.

Ready to elevate your packaging to new heights? Contact our expert team today to explore the endless possibilities of embossing and debossing. Let’s create custom packaging that not only stands out visually but also leaves a lasting tactile impression on your customers!