Table Of Content

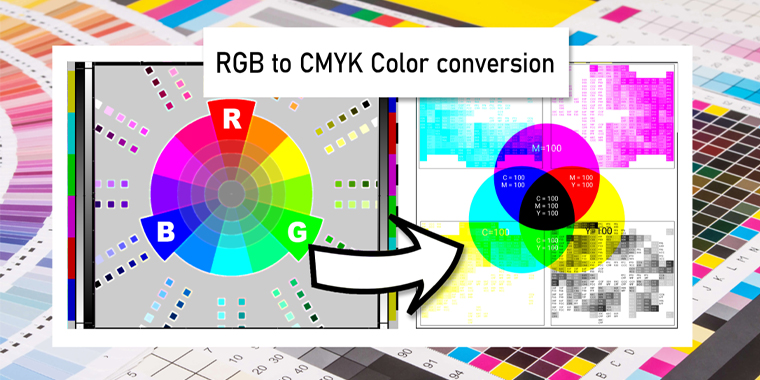

Colors are powerful tools for designing packaging. They create an emotional connection with customers. Designers struggle for accurate colors in print as they appear on a digital screen. RGB (Red, Green, Blue) is the color system used for digital designs and CMYK (Cyan, Magenta, Yellow, Black) is used for printing. Some colors in RGB don’t exist in CMYK. This can lead to inaccurate prints.

This blog will explain why and how RGB is converted into CMYK, without losing color quality. So, why wait any longer? Let’s start reading!

RGB and CMYK Color Models

It's important to understand the basics of RGB and CMYK color models. Their key features and differences are explained below:

What Really is RGB?

This color model is used for digital screens like computers. It works by combining light in different intensities. With more light, the colors become more vibrant.

What Exactly is CMYK?

This color model is used for printing. It removes light from a white background to form different shades such as white cardboard boxes. Some bright

RGB colors cannot be recreated in CMYK.

CMYK VS. RGB Printing

- CMYK is for printing, but the other is for screens.

- CMYK is subtractive, while the second one is additive.

- RGB has a wider color range.

- Printed colors may appear duller than screen colors.

Due to these differences, proper conversion is essential for high-quality prints.

Why Convert RGB to CMYK for Packaging?

If you don’t convert your design before printing, the printer will do it automatically. This can lead to unexpected color changes. Here’s why manual conversion is important:

- This ensures your packaging looks as close to your original design as possible.

- It prevents color mismatches and unwanted dullness.

- In this way, it is ensured that colors appear sharp and professional.

- Most packaging manufacturers require CMYK files for print-ready designs.

By converting before printing, you have full control over how colors appear.

Methods to Convert RGB to CMYK Without Losing Color

Let’s explore the best ways to convert RGB to CMYK correctly. These are discussed below:

1. Convert RGB to CMYK Using Photoshop

It is a powerful tool for color management. Follow these steps:

- Step No 1: Open your file.

- Step No 2: Click on Image > Mode > CMYK Color.

- Step No 3: Some colors may look different after conversion. Adjust them using Curves to bring back vibrancy.

- Step No 4: Save the file in PDF format for high-quality printing.

2. Convert RGB to CMYK in Illustrator

This is great for packaging designs if you’re working with vector graphics. To convert colors:

- Step No 1: Open your design in Illustrator.

- Step No 2: File > Document Color Mode > CMYK Color.

- Step No 3: If some colors look dull, go to Edit > Edit Colors > Recolor Artwork to manually adjust shades.

- Step No 4: Save the file in a print-ready format (PDF or AI file).

3. Use an Online RGB to CMYK Converter

Online tools like Canva’s CMYK converter can help. Upload your image, and the tool will convert the colors automatically. However, manual adjustments may still be needed. It is useful for colored boxes.

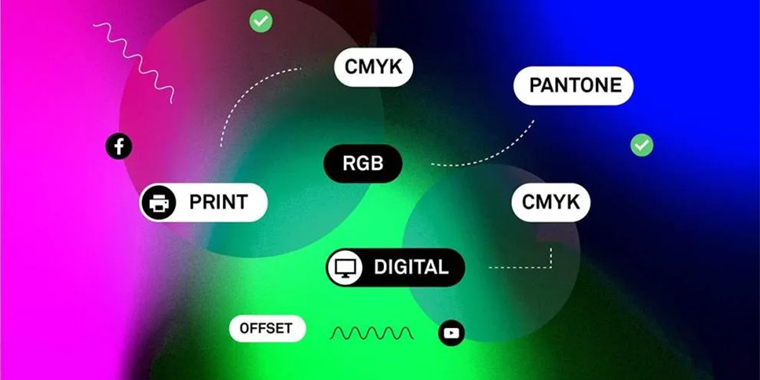

4. Convert RGB to PMS Colors

If exact color matching is required, converting RGB to PMS (Pantone Matching System) is a good option. PMS colors are predefined shades used for consistency. These are ideal for colored mailer boxes. This conversion can be done in Illustrator or by online Pantone tools.

After Conversion How to Maintain the Vibrancy of Colors

To keep your colors bright on different packaging materials like custom printed gift boxes, let’s discuss some tips:

- Tip No 1: Start your design in CMYK mode. It prevents unwanted surprises later.

- Tip No 2: Manually adjust colors after conversion to fine-tune the shades.

- Tip No 3: Use premium printing methods for accurate colors.

- Tip No 4: Soft-proof your design to see how it will look in CMYK before printing.

Common Mistakes to Avoid When Converting RGB to CMYK

Many designers make mistakes when converting colors. Here are some things to watch out for:

- Forgetting to Convert Before Printing – The printer will do it automatically, often with poor results. Always convert manually before finalizing your design.

- Using Low-Resolution Images – Low-quality images can look pixelated in print. Ensure a minimum resolution of 300 DPI for clear prints.

- Ignoring Color Proofing – Failing to check your colors before printing can lead to dull or mismatched shades. Always preview CMYK colors before printing. Especially for color labels.

Also Read: How CMYK Printing is Changing the Packaging Printing Trends

Final Thoughts:

RGB to CMYK conversion is necessary for accurate colors in packaging printing. Without proper conversion, bright digital designs may look faded or inaccurate when printed. By following the right methods, using professional design software, and making manual adjustments, you can maintain color quality and achieve stunning printed results.

At Custom Designs Boxes, we specialize in high-quality, color-accurate packaging solutions. Whether you’re a new startup or an established brand, we ensure your packaging prints look perfect every time. Contact us today via email at sales@customdesignsboxes.com for expert packaging solutions that bring your designs to life!