Table Of Content

Desire to offer high-quality packaging that buys at a glance? The quickest answer is “offset printing”.

Branded boxes require a perfect color match, crisp image, and clear typography - all at economical rates - and that is where offset printing comes in. It promises professional outcomes while keeping the costs low. Indeed, this (and digital printing) is a much more cost-effective method compared to the short-run methods.

Remember, packaging done with offset printing provides uniformity in color and detail, particularly when it comes to cartons, labels, boxes, and mylar bags that include foil in their build.

What Is Offset Printing?

The high-precision method of transferring inked images onto rubber blankets (by using metal plates), followed by printing on the chosen surface, is known as offset printing. This indirect mechanism eliminates direct interaction between plates and materials, which in turn produces cleaner images (due to smooth ink distribution) and an extended plate life.

The three primary parts of the system - impression cylinders, rubber blankets, and printing plates - interact in unison to function. Moreover, a distinct color layer is carried by each plate, usually using the CMYK method. It makes possible:

- Precise color registration

- Reproduction of fine details

Uniform color output and cost-effectiveness in large production runs are the main benefits. From smoother ink coverage to precise color layering, think of it as the most popular method for commercial printing, books, magazines, brochures, and custom packaging. It is best for every project where volume and accuracy are crucial.

04 Most Popular Types of Offset Printing

Understanding the offset printing workflow helps businesses appreciate why the results are so consistent. Here are the variations of offset printing used in the market, depending on the requirements of the packaging and the scale of production.

Sheet-Fed Offset Printing

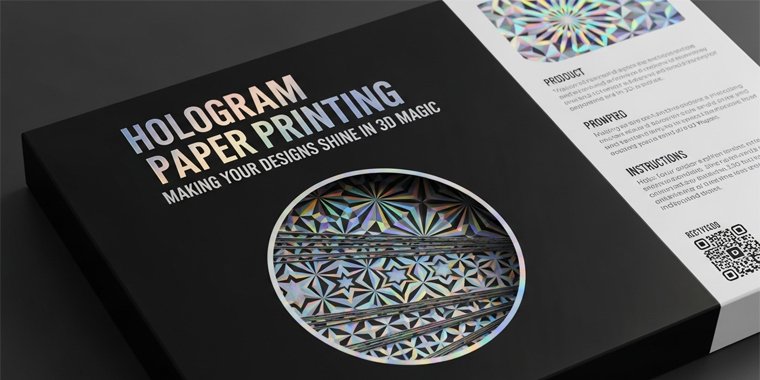

A sheet-fed printing, as the name implies, is a process where individual sheets of paper or paperboard are fed through the printing press. Yes, one sheet at a time for precise control over color. This approach is favored for luxurious packaging that demands clarity of detail, brilliant colors, and reliable quality simply because of its precision and adaptability.

- Best for short to medium print runs.

- Commonly used for folding cartons

- Performs well with heavier paperboards.

- Compatible with specialty finishes (for instance, embossing, foil stamping, spot UV, and custom coatings).

- Suitable for premium rigid boxes

Web Offset Printing

Web offset involves the use of a continuous roll of paper running through the press at high speed. It is meant to be used in high-volume production. Furthermore, it has two varieties:

- Heatset web offset produces glossy brochures, catalogs, and packaging inserts with flawless finishes by rapidly curing ink using heated dryers.

- Coldset web offset is more cost-effective and dries naturally by absorption; it is frequently used for bulk printed goods, manuals, and newspapers.

For large-scale packaging projects, web offset would greatly reduce the offset packaging printing unit cost. Surely, this makes it ideal when it comes to high-demand distribution.

Dry Offset Printing

When talking about specialized offset variations, the dry offset method tops the chart. A waterless kind of offset printing that does away with the dampening solution used in conventional presses is called dry offset printing. Most importantly, ink transfer is instead managed by specially coated plates.

Pictures printed with this technique have crisper edges, more uniform color, and clearer pictures. Also, it is frequently used to print on non-porous surfaces where moisture-based printing would not work, such as plastic tubes, cups, lids, and packaging containers.

Perfecting Offset Printing

This sophisticated press setup does not require separate runs because it prints on both sides of the paper in one pass. This greatly speeds up production, cuts down on handling time, and saves labor expenses. For materials that need precision alignment, it guarantees exact front-to-back registration.

In commercial and package printing, where consistency and efficiency are crucial, perfecting presses are usually utilized. This supports high-volume, double-sided output while preserving print quality by optimizing workflow and reducing paper disturbance.

Advantages of Offset Printing on a Professional Basis

The industry standard for high-volume, high-precision printing is still offset printing. Their advantages are as follows:

The Quality and Sharpness of Images

The designs are always excellent in terms of clarity and resolution. Considering how the image is transferred evenly by applying the ink made on the plate onto the blanket and the paper, offset printing significantly helps you get rid of distortion to produce sharp text. It takes care of tiny details!

Exact Color Representation + Consistency

Offset presses can accurately reproduce colors in huge print runs after they are tuned. In order to preserve brand continuity and provide a trustworthy visual identity, each unit keeps the same shade and tone.

Large Quantities

Though the setup cost is higher in the first instance, offset printing becomes highly cost-effective with an increase in the number of copies to be printed. Bulk orders are cheaper per unit, making it efficient when mass requirements are proposed.

Paper and Finish Variety

The number of paper stocks, weights, and finishes that are supported by offset printing is plenty. In fact, it readily adjusts to a variety of packaging and branding needs, from plain cardboard to metallic foils and coatings.

What is the Cost Structure

Because it requires plate production, calibration, and press installation, the initial setup costs are higher. However, the cost per unit drastically decreases once production starts. It is perfect for large orders because of its pricing structure. The final price is determined by:

- Number of items

- The quantity of colors

- Type of paperboard

- Coatings and finishes

- Plate preparation

- Press time

Over time, offset becomes substantially less expensive than digital alternatives for companies printing large quantities of packaging.

Sustainability in Modern Offset Printing

In order to deal with environmental concerns and conform to sustainable packaging methods, offset printing has undergone substantial evolution in recent years.

- Nowadays, a lot of presses rely on soy-based inks, which lessen the need for petroleum-based inks and cut down on volatile organic compounds.

- Water-based varnishes and low-VOC coatings also lessen the production of hazardous chemicals while preserving the long-term reliability and beauty of prints.

- With the advent of efficient waterless offset technologies, dampening solutions are no longer necessary, and chemical waste, energy, and water use are all decreased.

- Additionally, offset printing encourages the use of FSC-certified and recycled paperboard, encouraging companies to continue producing high-quality packaging while preventing deforestation.

- Its great volume efficiency reduces material waste in comparison to digital approaches that are trial-and-error or short-run.

- Plus, offset's accurate ink transfer minimizes over-inking, which eliminates its negative effects on the ecosystem.

Offset Printing vs Digital Printing

Many businesses compare offset and digital printing before choosing a packaging solution.

|

Feature | Offset Printing | Digital Printing |

| Best For | Large production runs | Small batches, prototypes, personalized items |

| Setup Time | Higher initial setup due to plates | Quick setup, minimal preparation |

| Color Consistency | Excellent; identical colors across long runs | Moderate; slight variation may occur in large volumes |

| Detail & Sharpness | Very high; crisp images and text | Good, but less precise for fine details on large runs |

| Cost Efficiency | Low per unit at high volumes | Cost-effective only for small runs; high volume is expensive |

| Flexibility | Limited; changes require new plates | Highly flexible; easy to modify designs |

| Turnaround Speed | Slower setup, but fast for mass production | Fast for short runs or urgent projects |

| Best Use in Packaging | Luxury display boxes, folding cartons, labels in bulk | Personalized labels, short-run packaging, prototypes |

Read More: How Die Cutting Works in Printing? Everything You Need to Know

Conclusion

In 2026, offset printing remains the most beneficial to professional packaging since it is the only one that balances quality, cost, and sustainability. Between the knowledge of what offset printing is to the assessment of the cost, businesses stand to benefit in the long run by making the decision of selecting offset printing for high-volume and high-impact packaging.

Using new equipment, materials with high eco-friendliness, and hybrid processes, the offset printing is adjusted to the contemporary needs and maintains the high quality of the final output.

Custom Design Boxes is the company that you rely on when it comes to high-quality and reliable offset printing services. Dial 888-385-1812, and wise heads will help you on your way with your next project.