Table Of Content

Screen printing is a reliable method to get vibrant and durable prints. This is a trusted printed method that has existed for decades.

It is used for different purposes, such as packaging and home decor. Knowing what screen printing is essential for you if you’re a business owner or want to start one.

This blog post will cover how screen printing works and compare it with other printing methods. So keep on reading to get insight into this printing technique!

What is Screen Printing?

Screen printing is the process of transferring a design onto a surface by pressing ink through a mesh screen. The screen acts as a stencil, allowing ink to pass through certain areas to create the desired design.

This technique is applicable on different surfaces, including:

- Fabrics: T-shirts and hoodies.

- Paper: Posters, custom paper bags, and business cards.

- Plastic & Glass: Bottles, signage, and packaging boxes.

- Metal & Wood: Custom decor, signs, and plaques.

Examples of Screen Printing

Screen printing is used in several industries. Some of them are discussed below:

-

Packaging

It is used in the packaging industry to provide bold and durable results on custom boxes with logos.

-

Home Decor

For the home decor industry, screen printing provides personalized prints for curtains, pillows, and wall art.

-

Promotional Items

This printing method is applied on mugs, tote bags, and pens for promotional purposes.

-

Corporate Branding

For branding, this technique is used on employee uniforms, branded notebooks, and gift packaging.

Screen Printing Equipment

You'll need the right equipment to get excellent results from screen printing. These include:

1. Screens

It is made from mesh and stretched over a frame. These are available in numerous detail levels.

2. Screen Printing Ink

There are different types of ink used for this printing method, such as water-based ink.

3. Squeegee

It is a must-have tool for evenly applying ink.

4. Screen Printing Press

It helps to align the screen and material to get precise prints.

5. Curing Equipment

Heat presses and flash dryers are used to set the ink.

6. Supplies

Screen printing supplies include emulsions, cleaning solutions, and scrapers.

How Does Screen Printing Work?

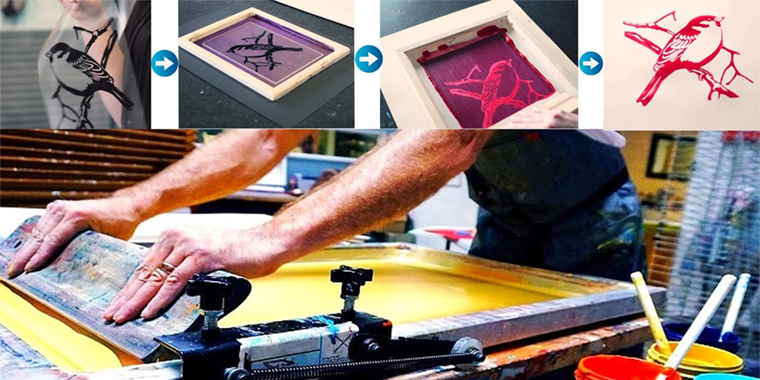

The screen printing process follows some steps to ensure accuracy. Following are the 6 steps of this process:

Step 1. Design Preparation

The process begins with creating or selecting a design. This design is digitized using software to ensure precision.

Step 2. Preparing the Screen

A mesh screen is coated with an emulsion. After drying, it is exposed to UV light. This hardens the emulsion, except in the areas where the design blocks the light. The unexposed emulsion is washed away, leaving the design on the screen.

Step 3. Setting Up the Machine

A manual screen printing machine is used for small batches, while an automatic screen printing machine is used for higher volumes. The material is placed securely under the mounted screen.

Step 4. Printing the Design

Ink is poured onto the screen and pushed through the stencil. This ensures even coverage and vibrant results on different products like glassine bags.

Step 5. Curing the Ink

The printed material is then dried using a heat press or conveyor dryer. This keeps the ink permanently attached to the surface.

Step 6. Quality Check

Finally, the product is checked for any flaws.

Advantages & Disadvantages of Screen Printing

To help you develop a better understanding of this printing method, let’s review its strengths and limitations:

|

Advantages | Disadvantages |

| Vibrant prints that remain durable over time. | Not suitable for small or single-unit runs due to setup costs. |

| Can be used on a wide range of materials, including fabric and glass. | Preparing screens can be a lengthy process. |

| Allows for intricate and detailed designs, especially with multi-layered prints. | Each color requires a separate screen, increasing time and costs for multicolor designs for colored boxes. |

| The cost per unit decreases significantly with higher quantities. | Operating the machines and ensuring quality prints need expertise and experience. |

| Prints retain their quality longer than other printing methods. | Uses chemicals that can impact the environment if not managed properly. |

Difference Between Screen Printing and Other Printing Techniques

Let’s review the key features of printing techniques like DTG (Direct-to-Garment), DTF (Direct-to-Film), sublimation, and heat press printing. Here’s a detailed comparison:

| Feature | Screen Printing | DTG Printing | Sublimation | Heat Press |

| Durability | Extremely long-lasting | Good | Excellent (on polyester) | Moderate |

| Vibrancy | Bright and bold colors | Moderate | Bright (on white surfaces) | Decent |

| Cost-Effectiveness | Cheaper for bulk orders | Expensive for bulk orders | High initial setup cost | Low for small orders |

| Applications | Wide range of materials | Fabric only | Limited to specific surfaces | Fabric and paper tube packaging |

While the comparison of DTG vs screen printing or sublimation vs screen printing shows that the selection depends on your needs. However, custom screen printing remains the most affordable option for large-scale production.

Also Read: What is Digital Printing

Final Words:

Screen printing is a versatile and budget-friendly printing method. This makes it the perfect choice for businesses. Screen printing offers excellent quality if you’re looking to produce custom apparel boxes or unique promotional items.

At Custom Designs Boxes, we specialize in providing custom screen-printed packaging made for your brand. Let us help you create designs that leave a lasting impression. Contact us today via email at sales@customdesignsboxes.com to get started with premium screen-printed solutions!