Table Of Content

Digital printing is changing the course of printing for businesses. Conventional printing requires plates or screens, but digital printing uses advanced technology to transfer images directly onto the material.

This kind of printing is efficient and produces excellent results. It has various applications, such as promotional materials and product packaging.

But you may wonder what is digital printing, and why it is changing the printing game. In this blog, we’ll learn everything about digital printing by exploring its advantages, types, and applications. We’ll also address common questions to help you understand its role in modern printing, so keep reading!

What is Digital Printing?

Digital printing is a process in which graphics made using design software are printed directly onto a material. There is no need for printing plates, which makes it a faster and cost-effective option for small and medium-sized projects.

Digital printing technology is compatible with various materials. These include paper, cardboard, plastic, and fabric. This printing method is highly versatile for packaging and other industries.

Digital printing machines include digital printers and digital presses. Digital printers are suitable for personal use and are smaller in size. On the other hand, commercial printing presses are used for industrial projects of larger scale.

Digital Printing Examples and Applications

Digital printing has a wide range of applications; let’s discuss some of them:

Customized Packaging

Brands use digital printing to create attractive custom boxes with logos, and other packaging materials.

Marketing Materials

Digital printing provides perfect results for promotional campaigns. Normally, brochures and flyers are used in this regard.

Textiles

Custom clothing and banners are produced using this kind of printing.

Signage

This printing is widely used to create durable and vibrant signs. These signs are useful for indoor and outdoor purposes.

Photo Books and Albums

Digital printing allows the creation of personalized photo products. It offers exceptional detail and color accuracy. These examples highlight the value of digital printing across industries.

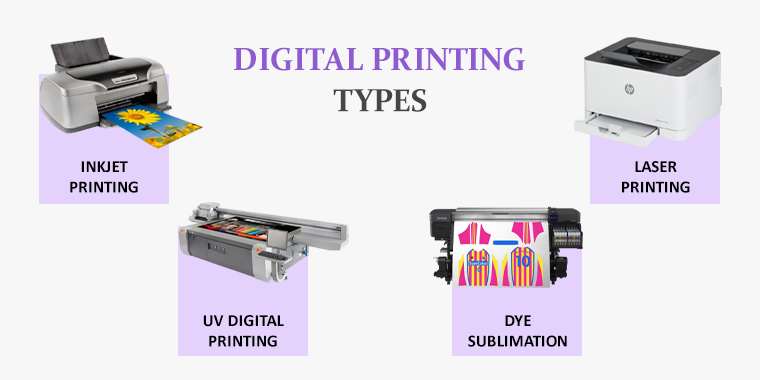

Types of Digital Printing

Digital printing consists of several methods. Each is suitable for specific applications. The most common types include:

Inkjet Printing

This method sprays liquid ink directly onto the surface. It is ideal for producing detailed images on various substrates. It is widely used for custom designs packaging, and promotional materials.

Laser Printing

Laser printers create sharp prints by using toner and heat. It is used for commercial printing on a smaller scale and office applications.

UV Digital Printing

This technique uses UV light to cure inks instantly. It’s perfect for printing on materials like plastic and metallic boxes. This is commonly used in luxury packaging.

Dye Sublimation

This method uses heat to transfer dye onto materials like fabric and ceramics. It is popular for promotional products.

Advantages of Digital Printing

Digital printing offers numerous benefits that make it a preferred choice for modern packaging and printing needs. Here’s why businesses use this technology:

Cost-effective for Short Runs

Digital printing does not require plates or setup costs. This makes it an affordable option for short and medium-sized printing projects.

Fast Turnaround Time

With no need for setup or drying time, digital printing enables quick production. It allows businesses to meet tight deadlines.

Customizable Data Printing

Brands can personalize each print with names, barcodes, or QR codes on shipping labels. It is perfect for targeted marketing and promotional offers.

Greener Option

Digital printing generates less waste and reduces chemical use. This supports environmentally friendly practices.

High-Quality Prints

Advanced digital printers produce vibrant colors and sharp details. It provides professional results with

smooth gradients.

Versatility in Materials

Digital printing is compatible with a variety of substrates. These include plastic, metal, and even holographic boxes. This makes it ideal for diverse packaging solutions.

Low Minimum Order Quantities (MOQs)

Businesses can print as few copies as needed. It is perfect for prototypes and limited-edition packaging. These advantages make digital printing an excellent choice for businesses looking for high-quality results with speed in their projects.

What Is The Difference Between Digital Printing And Normal Printing?

Digital printing and normal printing methods like offset or screen printing each have their strengths. Below is a table highlighting the key features of both printing methods in the industry.

| Feature | Digital Printing | Normal Printing (Offset & Screen) |

| Setup Time | No setup is required, prints directly from digital files | Requires plate-making and setup, increasing lead time |

| Cost for Short Runs | Cost-effective for small and medium print runs | Becomes cost-effective only for large volumes |

| Customization | Support data printing (e.g., names, barcodes, QR codes) | Limited personalization capabilities |

| Turnaround Time | Fast production with same-day or next-day delivery possible | Longer lead times due to setup and drying processes |

| Eco-Friendliness | Reduces material waste and uses less ink | Can generate more waste due to setup and excess ink |

| Print Quality | High-resolution prints with vibrant colors | Extremely high-quality and sharp details, especially for large runs |

| Material Compatibility | Works on plastic, fabric, and even metals. | Best for custom paper bags, cardboard boxes, and certain specialty materials. |

The choice depends on factors like quantity, cost, and complexity of design.

Also read: What is Lithographic Printing

Wrapping Up:

Now that we understand what digital printing is. We know it has changed the horizon of the printing and packaging industries. With its ability to produce high-quality results and customized designs quickly, it’s no wonder this technology continues to get popular.

At Custom Designs Boxes, we use advanced digital printing technology to deliver exceptional packaging solutions to fulfill your brand’s needs. If you are looking for personalized packaging or greener alternatives, we’ve got you covered. Contact us today via email at sales@customdesignsboxes.com to elevate your packaging with our help and make a lasting impression on your customers.