Table Of Content

Designing and creating beautiful yet effective packages of your choice for your brand is not a difficult task. This is the era of custom packaging, where everyone wants packaging that fits their products in the best way. Therefore, it is vital to understand what a dieline is in packaging. To avoid flaws in your packaging, the designing process should be according to the manufacturing standards and should meet the nature of the products. The dielines are quite crucial in the design process of packaging.

You’ll need vector art for all visual elements while designing any kind of packaging for your products. Moreover, die lines work as templates and include markings for the manufacturing process. It is a flat diagram, but your physical package largely depends on it. Mostly, designers and packaging officials deal with it, but anyone who is selling products must understand it. So, here, we aim to include everything you need to know about die lines for custom packaging.

What is a Dieline in Designing Packages?

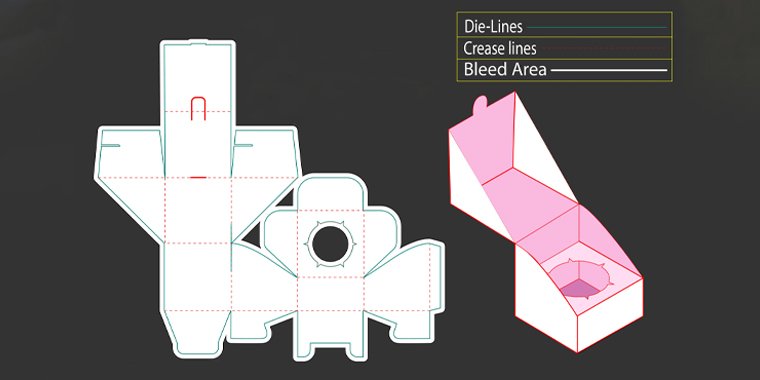

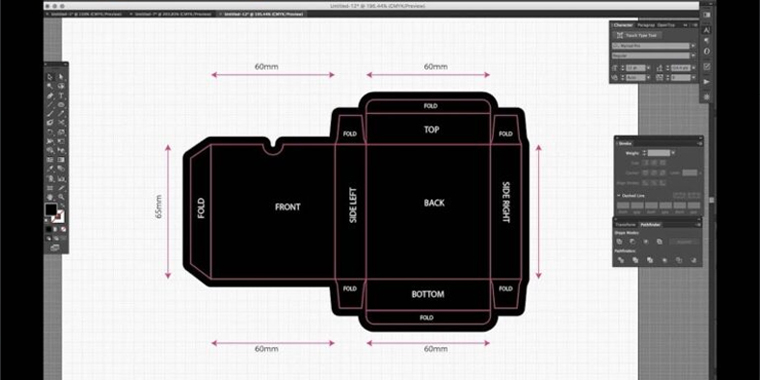

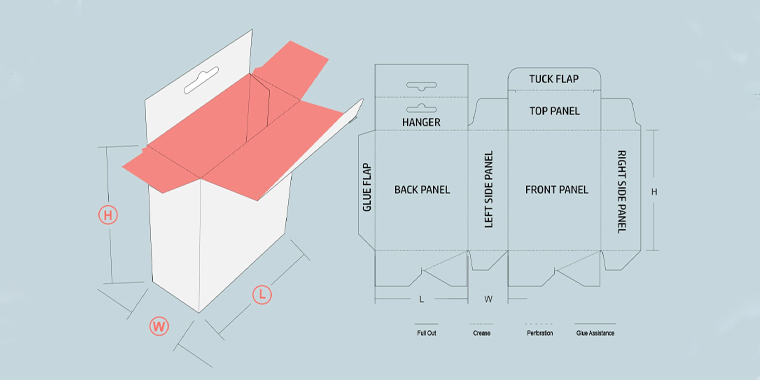

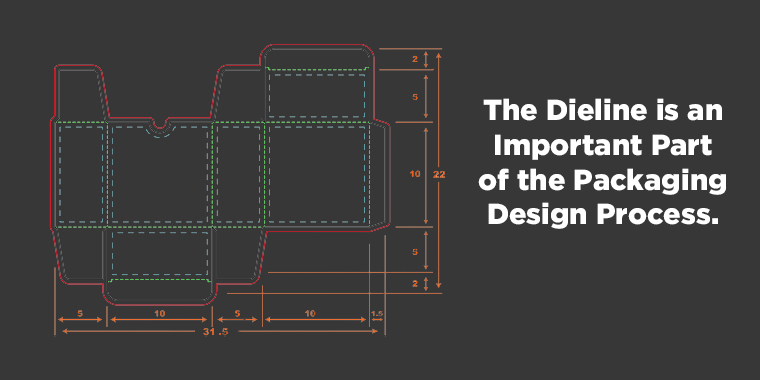

As said earlier, it works as a template that includes cut lines and markings that printers and cutting machines understand. This diagram can also include folding indications for the packaging. These lines serve as a graphic representation of the package you are going to have. Graphic designers use these cut lines to create layouts for any kind of packaging. These die-cut lines depend on the size, shape, and other dimensions of the packaging of your products that you want. Further, these lines indicate the area where the text will be printed. These help die-cutting experts to easily die-cut, crease, and perforate the custom box as per the requirements of customers. So, you’ll need to measure the dimensions of the box that is closest to your needs and then design it according to your product. Now that you know what die line is, let’s move on to the different types of it.

As said earlier, it works as a template that includes cut lines and markings that printers and cutting machines understand. This diagram can also include folding indications for the packaging. These lines serve as a graphic representation of the package you are going to have. Graphic designers use these cut lines to create layouts for any kind of packaging. These die-cut lines depend on the size, shape, and other dimensions of the packaging of your products that you want. Further, these lines indicate the area where the text will be printed. These help die-cutting experts to easily die-cut, crease, and perforate the custom box as per the requirements of customers. So, you’ll need to measure the dimensions of the box that is closest to your needs and then design it according to your product. Now that you know what die line is, let’s move on to the different types of it.

Type Of Die-lines

What type of die lines are included in the layout depends on the type of packaging. For instance, food packaging needs different dielines than the ones that are complex. Then there are different dye lines for packaging like labels, boxes, and bags.

So Here are All of the Types of Dye Lines:

Cut Lines

As every line’s function is different, cut lines work as a map for cutting machines and die-cutting experts. This helps to perfectly die-cut the box in the required shape, style, and size.

Fold Lines

Various packages include flaps and folds, so these lines indicate where the packaging is going to be folded. These lines indicate the folding area of the box.

Perforated Lines

Dotted or perforated lines indicate which areas of the packaging will be torn for a specific design. Tissue Boxes and Display Boxes are usually added with the perforated lines. These make packaging easy to unbox and you can turn simple boxes into appealing counter display boxes.

Bleed Lines

These lines indicate space between the substrate and the artwork to avoid imperfections.

Safety Lines

These lines provide enough margin to ensure that no artwork will be cut off during trimming.

Glue Tabs

They indicate the area where adhesive will be applied for constructing the parts of the package. Tuck-end, tuck top, and other boxes are also added with these glue tabs to provide a good assemble to a box.

Requirements Of Die Lines

Just as every process has requirements and considerations, so does the creation of die lines. You must first set up design software on your computer, such as Adobe Illustrator or Artioscad. Then what is a die line must be in vector art, as computers take inputs as mathematically described lines. You need to be really careful when putting specifications because a minor error can result in awful packaging. So, make sure your measurements are accurate depending on the product's needs. Further, the best practice for having perfect die lines is to print the prototype of the die lines and check for snap errors. Another important consideration for you is to select the document's color mode as CMYK while designing in Adobe Illustrator. It is important for achieving clear prints of dielines.

How Important are Dielines?

Anyone who wants to have the perfect packaging for his product wouldn’t ignore the importance of what is a die line. All the unique and attractive packages come into existence through an error-free dieline design process. Essentially, it is the first step towards creating perfect packaging for your products. Die-lines help you create packaging of any shape that suits your product. These lines are of great importance for the die-cutting process in packaging. Your artwork and other visual elements are protected through these lines. So, it is a dieline which makes sure you’ll have perfectly designed packaging.

Also Read: How to Measure Box Dimensions

Conclusion

What is a dieline? Well, die lines are kind of like instructions for die-cutting machines and printers. Dielines are designed digitally depending on the measurements and needs of the packaging. Whatever your packaging needs are, these lines ensure that the packaging will be created accurately. They help to achieve flawless packaging for your product as well as safeguard the artwork during the manufacturing process. If you want to get the desired custom boxes as per your product dimensions, contact us, and our graphic designers will design a perfect die-line for your products. Apart from this, Custom Designs Boxes has excellent expertise in packaging and one of the most experienced packaging suppliers in the USA. Thus, satisfying all your packaging needs is quite easy for us.