Table Of Content

The packaging box's dimensions are just as crucial as its appearance. Whether it's the shipping box or the packaging that your customers buy at stores, it's important to have the right box dimensions. Custom Designs Boxes serve as a line of defense against any damage during shipping or transition.

Products usually go through many places before reaching the customer’s doorstep or shopping cart. So, to ensure your products stay in prime condition, you need to have the right box measurements.

Additionally, since products vary in size and shape, you should be more cautious when preparing to measure your product and design the necessary box. There are some ways to measure accurate dimensions. Measurement tools or smartphone apps, for instance.

So, are you looking for the packaging dimensions so you’ll be able to get your desired boxes? Don't worry; this article has covered everything you need to know about measuring dimensions and their importance.

Why Accurate Box Dimensions Matter for Your Business?

Have you ever pondered why box dimensions are considered pivotal in the success of any brand? It is due to many factors. But the main ones are given below.

First is the protection. If dimensions are not correctly measured, you can not ensure that products fit snugly to prevent movement and damage during transit. A slight change can cost a lot.

The second is cost efficiency. With the dimensions, businesses optimize shipping costs by avoiding oversized boxes that can increase dimensional weight charges.

Then comes storage optimization. Knowledge of exact dimensions maximizes warehouse space by using appropriately sized boxes.

And, at last is customer satisfaction which has a direct impact on any business's success. The right-fit box provides a professional unboxing experience with well-fitted packaging.

How To Measure Exact Box Dimensions?

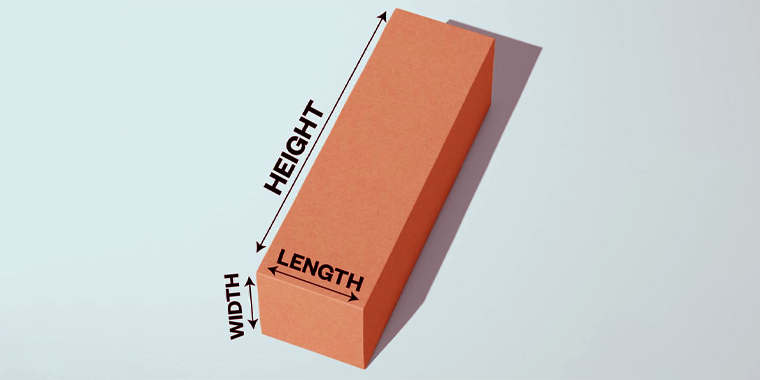

The more accurate the dimensions of the box, the more perfect your packaging gets. A box's dimensions are determined by a three-part metric: its length (l), width (w), and height (h).

1. Measure Length

When you look at the box from the top, the longest side of the box is called the length. Start with measuring length in inches or centimeters.

2. Measure Width

The horizontal part of the box when looking from the top, is called the width. Width decides how much space there will be for a product so be careful with it.

3. Measure Height

Now that you have measured other dimensions, you need to look at the perpendicular side to length and width. Measure from bottom to top and be careful as much as possible.

So, now you have the dimensions in terms of Length x Width x Height. To create the ideal box for your product, these dimensions must be precise. You have to assign the right dimensions for each of your packaging boxes, ranging from CBD boxes, jewelry boxes, or food boxes.

Additionally, if you don't think you're measuring it properly, we advise getting help and finishing the task. The point is not to compromise with box measurements.

Tools and Apps for Precise Measurements

There are some ways to measure accurate dimensions. Measurement tools or smartphone apps, for instance.

Read Also: How to Measure Box Dimensions Accurately

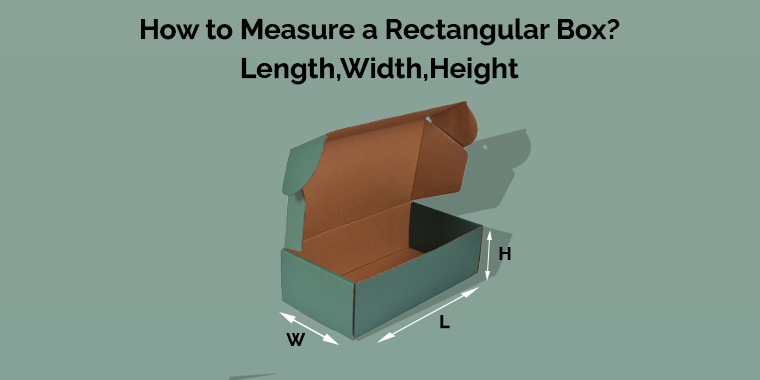

How to Measure a Rectangular Box?

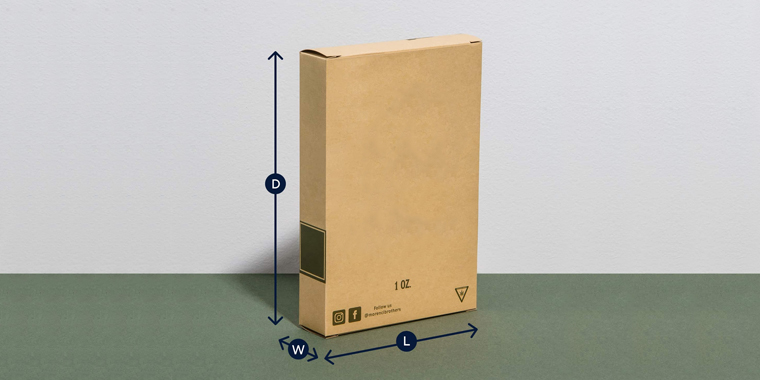

Measuring a rectangular box is easy compared to other shapes. Here is how to measure a square or rectangular box. For it you need measurement tape or any software.

Step 1: Measure Length (L)

The longest side of the box when looking from the top is length. Take tape and measure it. Note it down. A rectangular box may have a length of 12 inches, 10 inches, or any.

Step 2: Measure Width (W)

The shorter side when looking from the top, or from left to right, and vice versa. And measure it also with the tape.

Step 3: Measure Height (H)

The vertical side of the box from base to top is height. Measure it with tape.

Box Dimensions Formula: Length x Width x Height (L x W x H).

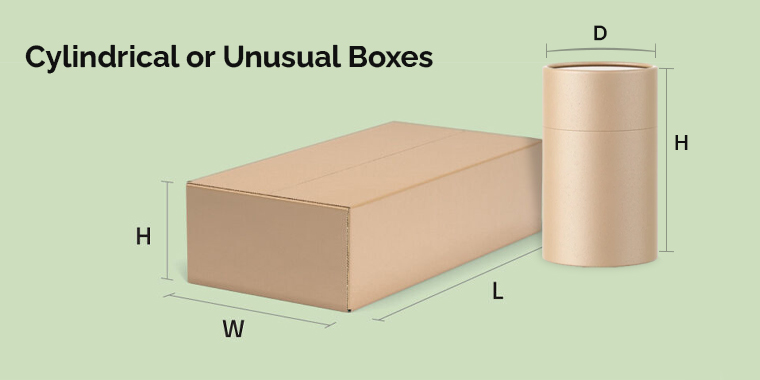

How to Measure Odd-Shaped or Cylindrical Packaging

If you deal with odd shapes, cylindrical, or round boxes, here is how to measure them. Here are the steps.

Step 1: Measure Height

Take a measuring tape to measure the height from the base to the top. For a cylindrical box, measure from the bottom to the top of the cylinder.

Step 2: Measure Diameter (For Cylinders)

After measuring height, now measure the widest point across the circular section. A 6-inch diameter cylinder would be 6 inches wide across the top.

Step 2: Measure Girth (For Odd Shapes)

For odd-shaped boxes, wrap the tape around the widest part of the object. A cylindrical package with a height of 10 inches and a width of 6 inches would have a girth of 32 inches (2 x height + 2 x width).

Here is how the dimensions of cylindrical and odd-shaped boxes are measured.

How to Measure the Girth of Cylindrical or Unusual Boxes

To measure the packaging dimensions of a custom shaped boxes, you need to measure its girth. Some products require different shapes, so to design suitable boxes for them you’ll need measurements.

Take a measuring tape and find the distance around the box’s widest point. To find the box's girth, multiply the box's height and width by 2, then add the results.

How to Measure Bag Dimensions?

Bags are daily-use items. Being a retailer, online business owner, or even an individual, the bag dimensions are also essential to know for many reasons.

Here is how to measure the bag’s dimensions:

Step 1: Measure Width

Lay the bag flat and measure across its width. Whether it is square or has any shape. A plastic bag could have a width of 10 inches.

Step 2: Measure Height

Now, measure the length from the bottom to the top edge of the bag. The height of a bag is maybe 15 inches.

Step 3: Measure Depth (If Applicable)

For bags with a side gusset, measure the depth by opening the bag and measuring the width of the gusset. A bag might have a 5-inch depth.

Internal vs. External Box Dimensions: What’s the Difference?

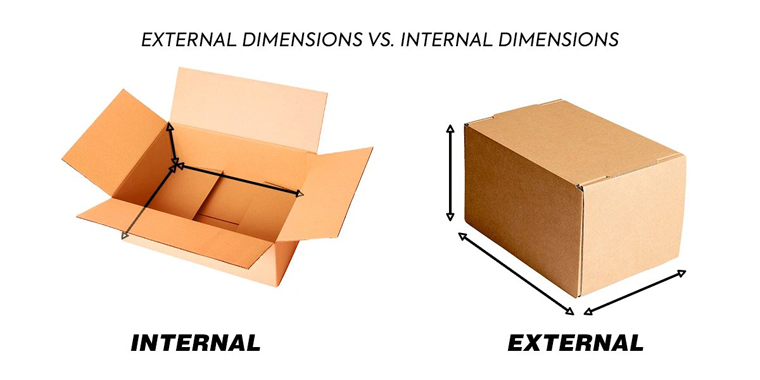

Have you ever thought of measuring the box's internal and external sides? There is always a slight difference between them.

For product packing, measuring the internal side is important for perfect fit. And, for shipping and box storage, measuring the external side is essential.

Internal Box Dimensions

The internal dimensions of the box are essentially important as it is exactly how much space there will be for your products. For safe transportation and to avoid excess space, you need to measure the box’s interior. The internal dimensions of a box, while less visible on its surface, have greater significance for any product you sell. Therefore, if you are a manufacturer that ships products, get the internal dimensions for accurate measurements.

External Box Dimensions

External dimensions are also significant because they reveal the total size of the box. For shipping purposes, you’ll need to measure the external dimensions.

To make things clearer, if a box has internal dimensions of 10” x 10” x 6”, its exterior measurements would be 10 ⅜” x 10 ⅜” x 6 ⅝” and a half inches.

It is worth noting that when using corrugated material to ship fragile products, the difference between internal and external dimensions is caused by “Flutes”. Those flutes are made of two pieces of sturdy paperboard for the best possible shipping protection.

Although the external dimensions indicate the overall size of the box, always measure internal box dimensions to make sure your product fits in the packaging.

How To Calculate the Volume of a Box? Formula and Examples

Why do you need to measure the volume of the box? You can determine how much room the box will require in your inventory by looking at its volume. Further, to optimize your cost of the packaging, first, you need to measure the volume of the box. For calculating volume, you must have length, width, and height.

You can now calculate the box's volume using the simple formula “L x W x H.” By measuring the box's volume, you can also determine how much room it will take up in warehouses as a single unit.

Volume measurement formula: If the box’s length is 10, height is 8, and width is 5, its volume will be:

Volume of the Box: Length x Width x Height = 10x8x5

The volume of the Box = 400 m3

Selecting the Perfect Box Size for Your Products

Always take your product into account when choosing the appropriate box size. Nobody wants a box that increases their costs in addition to fitting their product poorly. It is sensible to consider your product before designing packaging for it.

If you put a small product in a large box, you are not just wasting the packaging material, but also disappointing your customers. You can’t afford that, right?

So, it’d be smart to run tests and measure the accurate dimensions of the Box according to the product. Additionally, to deliver products safely and in the right size boxes, you should consider shipping situations.

How to Measure Dimensions for Shipping?

Shipping is an essential process, and knowing about box dimensions is essential. The right dimensions help keep products safe and secure, provide customers with well-maintained products, and reduce shipping costs.

So, here is how to measure the box for shipping:

Step 1: Measure External Dimensions

Firstly, measure the length, width, and height of the packed box from the outside. For example, a shipping box may be 15” (L) x 10” (W) x 8” (H).

With the above volume dimensions, calculate the volume, dimensions, and sides of the box.

Step 2: Calculate Dimensional Weight

Now, use the formula Length x Width x Height ÷ 139 (for inches) or ÷ 5000 (for cm).

For example, a box measuring 15” x 10” x 8” has a dimensional weight of 8.62 lbs (15 x 10 x 8 ÷ 139).

Step 3: Consider Box Material

At the end, make sure to account for extra padding or space if fragile items require cushioning.

Impact of Box Dimensions on Shipping Costs

Worldwide shipping costs are high, so it's best to stay informed about changes in shipping prices. Shipping companies charge based on the dimensional weight of the box.

Using appropriately sized boxes for products will save you from paying extra. Therefore, make sure your boxes incorporate the products you are delivering. Measure the dimensions of the box accurately and save extra shipping costs.

Common Mistakes to Avoid When Measuring Box Dimensions

People commit many mistakes while measuring box dimensions. Here are a few things to keep in mind to avoid mistakes.

Not Double-Checking Measurements: A 1-inch mistake could lead to using the wrong box size, increasing shipping costs.

Forgetting to Measure Internal Dimensions: A box with thick walls can reduce internal space, leaving insufficient room for the product.

Using Incorrect Tools: A flimsy measuring tape can lead to errors in dimensions, affecting box design.

Ignoring Material Thickness: Corrugated boxes have thicker walls that need to be factored into external measurements.

Best Measuring Tools and Apps for Box Dimensions

How can you measure the box? What tools or apps do you need? Here is all about ensuring tools and apps.

- The first one is Measuring Tape. It is A flexible, easy-to-use tool for measuring basic dimensions.

- Another method is Digital Calipers. They are innovative and for more precise measurements, especially with smaller packaging.

- The latest measurement tools are Smartphone Apps. apps are present on iOS/Android. These tools use augmented reality (AR) to measure dimensions through your phone's camera.

- Another method is Box Volume Calculator (Online): you have to Input length, width, and height to quickly calculate box volume.

- The expensive ones are Laser Distance Measurers. They are ideal for larger packages where traditional tape measures are less effective.

Summing Up!

Accurate measurements are necessary before you can design the ideal packaging for your product. Measuring the precise box dimensions is more crucial than you might realize because your product's packaging requires extra care. We covered every necessary information in this article that will assist you in measuring the dimensions of a box.

Seeking an ideal packaging partner to get perfect-sized packaging boxes? Look no further than Custom Designs Boxes. We offer our customers innovative and stylish packaging options that offer sung fit for utmost protection. The best part? We offer discounts on wholesale custom packaging boxes to help you save a lot of money. Get in touch with us via email at sales@customdesignsboxes.com today!