Table Of Content

Packaging has three tiers: primary, secondary, and tertiary packaging. Collectively, they contribute to growing the business. Irrespective of the fact that it is new or established.

Primary packaging houses the exact products, secondary packaging makes groups of those products, and tertiary packaging is the outer layer that ensures the safe delivery of the products. Businesses focus on this type of packaging to increase their efficiency.

Knowing about tertiary packaging is essential if you are a business owner or aspire to start one. This blog post will explore tertiary packaging, its types, and applications. So, Let's kick off our discussion!

What Exactly is Tertiary Packaging?

If you are thinking about the definition of tertiary packaging, it's the final layer of packaging. The tertiary packaging market transports large quantities of goods. It is also known as bulk or transit packaging. It is designed to keep your products safe from external factors.

Examples of Tertiary Packaging

This packaging is available in different forms. Some common examples include:

- Pallets & Crates: These are used to transport large quantities of goods.

- Stretch & Shrink Wraps: They keep products thoroughly packed and protected.

- Corrugated Boxes With Lids: These boxes are used to store and transport packages.

- Protective Foam & Cushions: They absorb shocks, thus preventing damage.

- Bulk Containers: These are used to transport liquids and powders.

Types of Tertiary Packaging

The following are the most common types of this packaging in the market:

Rigid Packaging

It includes wooden crates, metal drums, and hard plastic containers. These are used for heavy goods.

Flexible Packaging

It contains stretch films and shrink wraps that are used for lightweight items.

Protective Packaging

This includes foam inserts and air cushions. They help to safeguard delicate products.

Bulk Containers

It consists of large sacks and barrels for liquids and granulated products.

Importance of Tertiary Packaging

Let’s review why it matters. The following are the reasons:

- Product Protection: Prevents damage during shipping and handling.

- Efficiency in Logistics: Helps in easy storage and bulk transportation.

- Cost Savings: Reduces loss due to lower risk of damage.

- Environment Friendly: Many tertiary packaging materials are recyclable and promote sustainable packaging.

- Better Handling: Facilitates automated packaging and transportation systems.

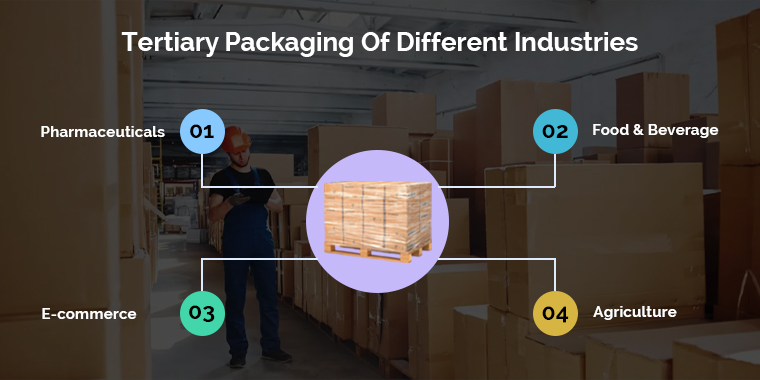

Applications in Different Industries

Tertiary packaging is used for a wide range of products, some of which are discussed below:

Pharmaceuticals

It ensures that medicines and medical supplies remain safe. Bulk shipments of drugs are packed in large cartons to maintain their integrity.

Food & Beverage

For delicate items like beverages, glass bottles, insulated containers, and pallets are used. For example, when Coca-Cola ships their cases, they are stacked on pallets and then wrapped in plastic.

E-commerce

Large businesses use corrugated boxes to keep products safe for shipping. For example, biscuits are packed in cartons and placed on pallets for transport.

Agriculture

For agricultural goods such as fruits, this packaging is used for distribution on a larger scale. Sacks and crates help in safe transport.Electronics and Machinery

Fragile electronic items require strong cartons to prevent damage. Pallets with foam inserts are commonly used.

Benefits & Drawbacks of Tertiary Packaging

This packaging provides many benefits, but it also has some drawbacks. Let’s review them to understand it completely:

Benefits

1. Minimizes Product Damage

It reduces the chances of breakage or leakage.

2. Enhances Efficiency

This type of packaging allows easy stacking and transportation.

3. Reduces Packaging Costs

Packaging in bulk reduces the need for excessive secondary packaging.

4. Supports Automation

This packaging is highly compatible with warehouse automation systems.

5. Greener Options

Many tertiary packaging materials are recyclable and biodegradable.

Drawbacks

1. Increased Material Use

Additional materials like pallets and shrink wraps are needed.

2. Higher Storage Requirements

This packaging is bulkier, so it needs more warehouse space.

3. Environmental Concerns

Some materials are not eco-friendly and contribute to waste.

4. Added Costs

It increases packaging and shipping costs for new businesses.

5. Complex Recycling Process

Some tertiary packaging materials require special recycling processes.

Secondary Packaging VS. Tertiary Packaging

Secondary packaging makes groups of primary packages. It includes boxes and wraps for display. These are essential for branding and presentation purposes in the market. Tertiary packaging is designed for bulk transport. It includes pallets and crates.

Best Practices of Tertiary Packaging for Business Efficiency

To maximize the benefits of tertiary packaging, businesses should focus on:

Select the Right Materials

Using durable and recyclable materials can enhance efficiency.

Standardizing Packaging Sizes

Consistent packaging sizes improve stacking and storage efficiency.

Implementing Automation

Packaging systems can speed up the process and reduce labor costs.

Reducing Waste

Minimizing excess packaging materials can lower costs and environmental impact.

Using Smart Packaging Solutions

Technologies such as QR codes can improve traceability.

Future Trends

Companies are shifting towards greener alternatives. Some emerging trends include:

- Biodegradable Stretch Films: It reduces plastic waste.

- Reusable Pallets and Crates: They help to lower costs and promote sustainability.

- Smart Packaging: It uses tracking systems for better logistics.

- Lightweight Materials: These reduce shipping weight and fuel consumption.

Also read: What Is Frustration-Free Packaging? Improved User Experience And Boosted Convenience

Final Words:

Tertiary packaging is essential to optimize supply chains. It protects products and reduces costs. Businesses across various industries rely on it for safe transportation and storage.

At Custom Designs Boxes, we specialize in providing excellent quality tertiary packaging solutions that meet your needs. These include folding cartons, corrugated boxes, and many more.

Contact us via email today at sales@customdesignsboxes.com to optimize your packaging process with reliable and sustainable options.