Table Of Content

Have you ever seen the small coloured dots, circles, and squares on your packaging and wondered what they are there for? The real meaning of colorful dots on packages is not related to health warnings or any kind of decoration. Actually, when you see them for the first time, they look attractive, but they serve a specific purpose.

We identify that most of the people assume that these color codes are telling you the situation of the food, whether they are fresh, healthy, or processed. Well, the confusion starts here, and the truth is that there is no connection between these dots and nutrition.

The color codes on packaging are part of the printing process. It is assembled by manufacturers to make sure that the colors on the packaging are consistent and accurate. Stay with us to the end, as we are exploring the guide, including the meaning of its black, blue, red, and green colors.

The best thing is that we will expose some common myths and show you what you have to identify when checking your food labels.

What is the Purpose of Color Codes on Food Packaging?

Color codes are the colored circles or squares that you see on the packaging of any product in the packaging industry. They are providing a technical function, and manufacturers use these marks on the packaging during the printing process. It will help them to maintain the quality of the printing when it comes to mass production.

Most of the food packaging industry uses the CMYK color model that includes cyan, magenta, yellow, and black inks. In the printing process, they applied each color in separate layers. For example, manufacturers use the CMYK model when printing custom cake boxes.

The color dots that are in square shape on the packaging remind printers to check that all the color plates are perfectly aligned. Plus, the colors are clearly and perfectly printed on the packaging.

Imagine if any of the colors are missing or the color plates are misaligned, they are clearly visible in the markers immediately. This process helps operators to fix issues before the production of thousands of defective packages.

Regarding their placement, they are positioned on the flap or edge of the packaging area. These marks don’t interfere with product information or branding. The most important thing is that these squares or dots are not linked to the food's suitability, safety, or nutritional value. Neither are they conveying any message to the consumers.

Do These Circles Indicate Food Quality or Safety?

The short answer to this question is no, they don’t indicate food quality or safety. However, the purpose of these color dots in specific countries like India is different. Where you see the purpose of printing color codes, indicate the flavor or information inside the food packaging. The color green indicates that the food is vegetarian, while red means it is non-vegetarian. From chip bags to product boxes, these color codes ensure your packaging is printed with accuracy.

What Do the Colored Dots on Chip Bags Mean?

The colored dots that you found on the chip bags are part of a standardized printing quality control system. It is used in the packaging industry, and you can usually see them as small circles, squares, and blocks in several colors that are known as printer’s color control patches.

Plus, they allow the manufacturers to verify that the ink is being used properly and that the color is properly aligned in the printing process. CMYK (Cyan, Magenta, Yellow, Black) is a process that is used to print most of the chip bags. Every color is printed in several layers, and the color dots portray each of these inks. The position of these dots will not interrupt the product information section and the bag’s branding.

When the printer applies these dots, they are probably checking the registration accuracy, color density, alignment of each layer, and ink quality. If one color is misaligned, missing, or too light, then it will immediately become noticeable with the help of these marks. The following process helps the printer catch the error in the early stages of production.

What is the Meaning Behind Each Color Dot?

When you saw the color codes on any packaging or bags, you may have found it simple. But the truth is that each color code has a specific function in the overall printing process. These color marks help manufacturers ensure the design consistency, color accuracy, and printing alignment during bulk or mass production. Here is the detailed explanation of what each color code actually represents:

1. Black Color

The first color in our list is black, which has the purpose of representing sharp details, including outlines, barcodes, and small text. The black color is called “K” in the CMYK process, which helps to enhance the readability and contrast of the background.

2. Blue Color

The blue color code is linked with the Cyan component of the CMYK model. The Cyan component is used to create color tones in the overall packaging design. The blue color verifies the alignment of the Cyan plate in the printing process.

When the blue control mark is not centered or appears dim, it indicates a problem in the printing process that should be corrected.

3. Red Color

The third color in our list is red, which represents a blend of magenta used to produce attractive hues and warmer tones. The red tones are used in sale highlights, logos, or essential brand elements.

Moreover, it helps the Quality Assurance Inspector to make sure that the red tones are printed properly. If the color is misaligned or the ink fades in this area, it will impact the product’s branding and visual appeal. So, the red color will help to maintain brand integrity and design quality.

In addition, it helps the Quality Assurance Inspector ensure the red tones are printed correctly. If the color is not aligning properly or fading in such areas, it will affect product branding and brand image.

4. Green Circle

Are you looking for what the green circle on food packaging indicates? Don’t worry. The green color is also part of the printer’s color test. It is either the blend of cyan and yellow or a dot color that is used to check the consistency in green areas of the design.

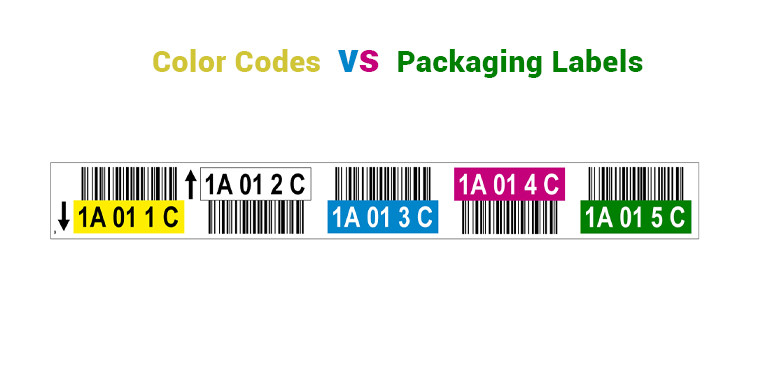

Color Codes vs. Other Packaging Labels

When you see the color codes on packaging, you might link them with the actual product information, but they are not. Both of them have entirely different purposes. The purpose of color codes is related to the printing process of packaging. At the same time, it might be different in some regions or countries.

However, packaging labels are like allergen warnings, expiration dates, ingredient lists, and nutritional facts that are printed especially for public understanding. Additionally, the expiration dates on the packaging indicate when the product expires or becomes unusable.

The nutrition labels help consumers make an informed decision regarding diet. Color codes help the quality assurance team ensure the accuracy and consistency of the package during the printing process.

In short, color code supports the printing alignment, but other packaging types, like pharmaceutical packaging, include warnings and separate icons to inform consumers.

Also Read: Is Packaged Foods A Good Career Path? Here’s The Guide

Where Are These Color Codes Usually Found?

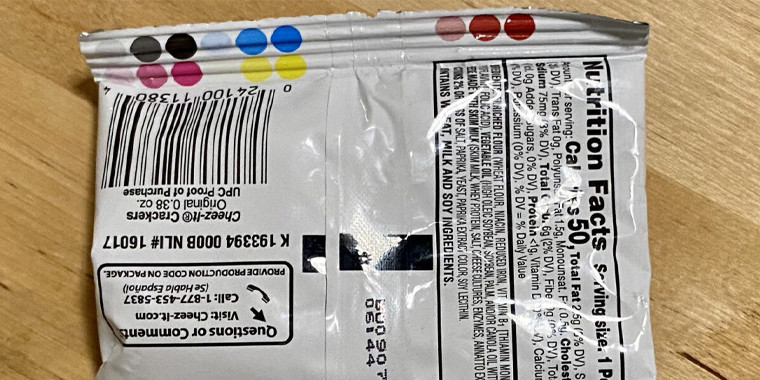

Have you ever found the small colored circles or squares on the food package? You might notice that they are placed in that area, which is less noticeable. These color codes are placed near barcodes, flaps, seams, or along the other edges of the packaging areas, as you can see on custom cookie boxes.

Talking about chip bags, they are often placed near the heat-sealed edges or the bottom seam. They are usually found near the glue flaps or along the fold on boxes and cartons. There is a purpose for the placement of these color codes, which helps printers to spot them without affecting the overall visual appeal of the package.

Plus, there is a difference in shape, size, or material of these color codes. But their location is consistent across several packaging types.

Conclusion

It is important to know the actual purpose and meaning of the color codes on food packaging. Most of the people relate these codes to the flavor and ingredients of the package, but they are actually related to the printing process before production.

These color codes help Quality Assurance Inspectors ensure the printing process of the packaging, its accuracy, and consistency.

Are you looking for someone who can help you with printing on food packaging? Choose Custom Designs Boxes to help you. Our expert designers and Quality Assurance team will create packaging designs and print them according to your preferences.