Table Of Content

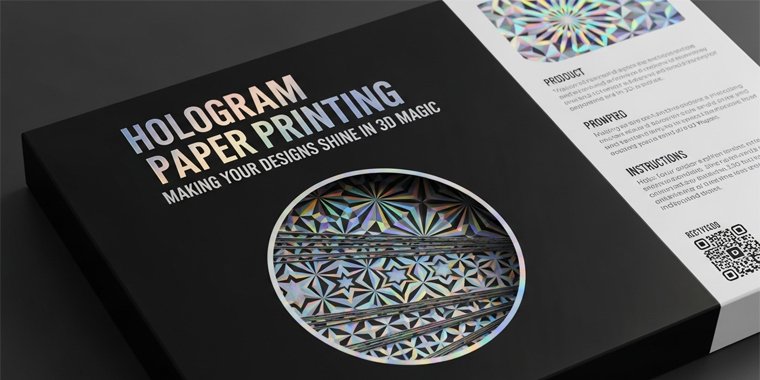

Stickers are a fun way to personalize products and add a unique touch to packaging. If you want to take your stickers to the next level, holographic stickers are the way. The color-changing effect of these stickers grabs attention instantly.

Making these stickers is easier than you think. Understanding the process is highly beneficial if you are a business owner looking to boost your sales.

This blog post will help you understand how to make holographic stickers while covering the materials and expert tips to ensure high-quality results. So, let’s get started!

What are Holographic Stickers?

A special kind of sticker paper is used to produce these stickers. It reflects light and produces different colors. The base material has a surface resembling a rainbow. It gives a metallic look.

These stickers and labels are used in product packaging and promotional materials. They offer a unique visual appeal that stands out.

Applications of Holographic Stickers

These stickers are used in numerous industries. Some applications are discussed below:

Packaging

Businesses use them to make and holographic decals.

Promotion

Many companies hand out holographic stickers for marketing purposes.

Personal Projects

People use them for custom laptop stickers, phone decals, and DIY crafts.

Security Labels

Some stickers have anti-counterfeit features, such as holographic paper printing for authentication.

Events

These are used for event passes and concert tickets

What are the Materials Required to Make Holographic Stickers?

To make gorgeous holographic stickers, you need perfect materials. These are discussed below:

Holographic Sticker Paper

Use the best holographic sticker paper, as it is the key material that gives stickers their shiny look. Select from matte or glossy options.

Inkjet or laser printer

Choose a printer that works well with sticker paper. Some printers struggle with thick materials, so check compatibility.

Design software

Programs like Adobe Illustrator, Photoshop, or free alternatives like Canva help create professional holographic sticker designs.

Laminating sheets

These provide extra protection and durability. This helps stickers last longer and prevents scratching.

Cutting tools

A Cricut machine or scissors can be used to cut stickers. A precision knife can also work.

Clear vinyl sticker paper

This keeps stickers waterproof. It also makes vinyl stickers more vibrant.

Tips to Make Superior Holographic Stickers

- Use Cricut holographic sticker paper for the best results.

- Keep designs bold to ensure they are visible on the reflective surface.

- Laminate these stickers to make them waterproof.

- Store sticker paper in a cool, dry place to prevent curling or damage.

- Consider testing different printer settings to achieve the most vibrant print quality.

How to Make Holographic Stickers at Home in Just 4 Simple Steps?

Let’s review how to make a hologram sticker at home with the following steps:

Step 1: Create Your Sticker Design

Start by designing your stickers using graphic design software. Make sure to:

- Use sharp images for a clear print.

- Choose vibrant colors that stand out against the holographic background.

- Add bold outlines or shadows to enhance visibility.

- Experiment with different holographic effects to maximize the unique appeal.

Step 2: Print on Holographic Sticker Paper

- Load the holographic sticker paper into your printer.

- Print a test page on regular paper first to check alignment.

- Adjust your printer settings for high-quality output. Select “photo” or “best” print quality for vibrant colors.

- Allow ink to dry before handling the stickers to prevent smudging.

Step 3: Laminate for Extra Protection

Laminating helps stickers last longer by adding a protective layer. There are two ways:

- Using a machine: Place a clear laminate sheet over your stickers and run it through the machine.

- Without a machine: Apply a clear vinyl sheet manually and smooth out air bubbles.

Laminating adds extra durability. This makes stickers more resistant to wear and tear.

Step 4: Cut the Stickers

- Upload your design file and select the right cutting settings on the Cricut machine.

- In case of manual cutting, use scissors for clean edges.

- A cutting machine ensures precision and a professional finish.

Advantages of Holographic Stickers

Holographic stickers offer many advantages. Let’s review them:

Unique and attractive look

Their shiny surface makes them stand out in the market.

Versatile applications

These are suitable for branding, packaging, and decorations.

Durable and waterproof

These stickers can withstand moisture and wear when laminated.

Customizable

These die cut stickers are available in various shapes.

Increases perceived value

Different brands use these stickers to increase the charm of their products.

Disadvantages of Holographic Stickers

Holographic stickers also have some disadvantages. These are discussed below:

Higher Production Cost

The special materials can be more expensive than regular paper stickers.

Printing Limitations

Some home printers may not support holographic paper properly.

Scratch Sensitivity

Without lamination, these stickers can get scratched easily.

Difficult to Cut Manually

Using a cutting machine ensures precise edges.

Limited Color Contrast

Designs with light colors may not show well on the reflective surface of holographic labels.

Also Read: The Importance of Considering the Feel of Your Embossed Stickers

Final Words:

Hopefully, you now know how to make holographic stickers. These stickers are perfect to add a premium touch to any product. They are used for packaging, or personal projects and enhance their shine and durability.

By using finishing techniques like lamination, you can ensure they last longer and maintain their vibrant appeal. At Custom Designs Boxes, we specialize in providing custom packaging solutions.

With our expertise in hologram sticker printing, we help businesses create amazing designs to leave a lasting impression. Contact us today via email at sales@customdesignsboxes.com to get the best holographic stickers!