Table Of Content

Packaging companies use different types of materials to make strong, customizable, lightweight, and printable designer boxes. Moreover, packaging manufacturers are looking for a new material stock that fits best with sensitive products and food products to retain their taste and flavor, and eco-friendly materials to support the eco-system. Versatile material options are available in the market.

These include kraft, cardboard, paperboard, corrugated, rigid, and chipboard. Looking at all the material options, chipboard proves to be a decent option.

Chipboard is an advanced material option with properties of sustainability, customization, and durability.

Let us learn more about chipboard in detail and what are the facts that make it distinct from others.

What is chipboard?

What do you know about chipboard? Say it or not, but you have seen it used it at least once in a lifetime. Its use is expanded. People just do not know what is it.

Chipboard is a thick paper. It is 100% made of recycled fiber and wood pulp. Other pieces are categorized on weight, however, chipboard is categorized on paper thickness.

It doesn't have corrugated channels inside it, making it more cost-effective and space-saving while providing top-class durability. It is so durable that the sticks of dynamite are made from it.

It comes in a variety of thicknesses, depending on the use. Not only that, but it is not all about chipboard. Let us learn more about it.

Major Facts About Chipboard That Make It Different From Other Material Options

Here are the major attributes of chipboard, that make it different from ordinary materials.

1. Chipboard is Not Cardboard or Corrugated

One common misconception is that chipboard is the same as cardboard or corrugated material. However, there are significant differences between these materials.

Cardboard, for instance, is often hollow inside. Also, it is solid and denser. However, corrugated material consists of a fluted layer sandwiched between two sheets of paperboard, giving it structural strength for shipping and storage purposes.

Whereas, chipboard is compact and not hollow. It provides a sturdier base for different applications like packaging, book covers, and crafting projects.

A 2023 case study by the Packaging Council of America found that businesses mistakenly using cardboard in place of chipboard saw a 20% reduction in product durability during transport. It creates havoc.

Chipboard's solid structure offered better protection and reduced product damage by 15%, showing why the distinction is crucial for effective packaging decisions.

2. Chipboard Has Varying Thickness and Types For Every Need

One of the standout features of chipboard is its availability in various thicknesses and densities, making it versatile for various purposes. A thick, dense chipboard is often used as a book cover due to its robustness, providing strong protection and durability.

Chipboard's density plays a critical role. According to research published by the Wood-Based Panels Journal in 2022, thicker chipboard used on construction sites or in furniture manufacturing can handle up to 30% more weight and impact compared to medium-density fiberboard (MDF).

It is said that builders and manufacturers favor chipboard for its cost-effectiveness and durability in high-traffic areas such as flooring and countertops.

3. Chipboard Has Enormous Uses

Chipboard has enormous uses. It plays a vital role in construction and furniture manufacturing. High-density chipboard made from wood pulp, not paper, is used to make floors, furniture, and even countertops.

The wood pulp is pressed into thick sheets to create a highly durable material that can withstand daily wear and tear. Floors made from chipboard can resist foot traffic, water, mud, paint, and even heavy machinery.

Furthermore, for contractors, chipboard outperforms standard plywood in terms of resistance to water damage. That is why it is an ideal choice for long-term and high-traffic applications.

4. Chipboard Is Commonly Used In Scrapbooking and DIY Projects

Chipboard is also a major material used in crafting, especially in scrapbooking and DIY projects.

Due to its thickness and texture, it is the perfect material for adding dimension to pages, making custom cut-outs for letters and shapes, and serving as a sturdy base for various creative endeavors.

It can also be covered with paper or fabric to create decorative items like picture frames, making it an incredibly versatile crafting tool.

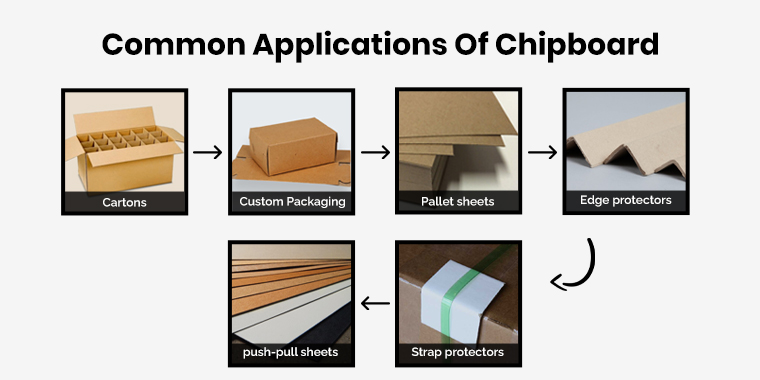

Common Applications Of Chipboard

The usage of chipboard is extensive. It is easily customizable in different thickness sheets, making it versatile. There are some given usages of chipboard. Its uses are enormous and used everywhere. These are the common places Chipboard has gotten a stronghold.

- Cartons

- Custom Packaging Boxes

- Pallet sheets

- Pallet pads

- Edge protectors

- Strap protectors

- push-pull sheets

Major Benefits Of Chipboard

The benefits of chipboard for packaging boxes are enormous. However, there are major advantages.

Eco-Friendly: First, chipboard is eco-friendly and sustainable. It is perfect for waste management. It is made from wood waste and can be recycled after use. Not only that, but it makes it recyclable and sustainable.

Cost-Effective: Secondly, it is very much economical. It comes at half price compared to plastic and other sources. It is thinner and lightweight. Furthermore, it saves the cost of shipping and freight of delivery.

Versatile: Thirdly, it is versatile. It can do all the tasks that plastic can do. It can be cut to spec for use in different types of cardboard boxes. Moreover, it handles heavy loads and is puncture-resistant. So, you know that the product is protected.

Making Chipboard From Raw Materials: Paper Converting

Paper converting is a term used to convert paper from wood pulp. Harvesting raw wood pulp material to convert into pieces for end use is called paper converting. This process involves:

- Harvesting Raw Material

- Pulping and Pressing

- Cutting and Shaping

- Finishing

- Final Product

Final Thoughts

Now you know what is chipboard. It is a special material used for many purposes. Its use in packaging is enormous. From creating packaging boxes for shipping to give perfect protection and easy handling, to creating display boxes to design them with visuals and illustrations to lure customers.

Its benefits for packaging boxes go beyond imagination. It is strong, designed with visuals, customizable in shapes and sizes, and printed with slogans and logos.

However, that is not all. Chipboard proves to be a cost-effective option for packaging. It is thin, and occupies less space, benefiting in shipping and transit.

If you want to create packaging boxes, mailer boxes, display boxes, or any special edition boxes, Custom Designs Boxes is here to benefit you with perfectly made chipboard material, and perfectly shaped boxes, designed with images and visuals. We offer you free shipping and free design consultation for affordable rates and huge discounts. Get your chipboard boxes from us, and boost your product effectiveness, handling, and presentation.